A Modern and Sustainable Option: Steel Framing

By Editorial Team

Updated on November 11, 2024

Steel framing is a growing trend in residential construction. While it first came onto the scene exclusively for commercial and industrial buildings, its qualities soon convinced homeowners, too.

If you're keen on installing steel framing, you’re on the right track! However, there are a few things to keep in mind about steel framing before jumping right in.

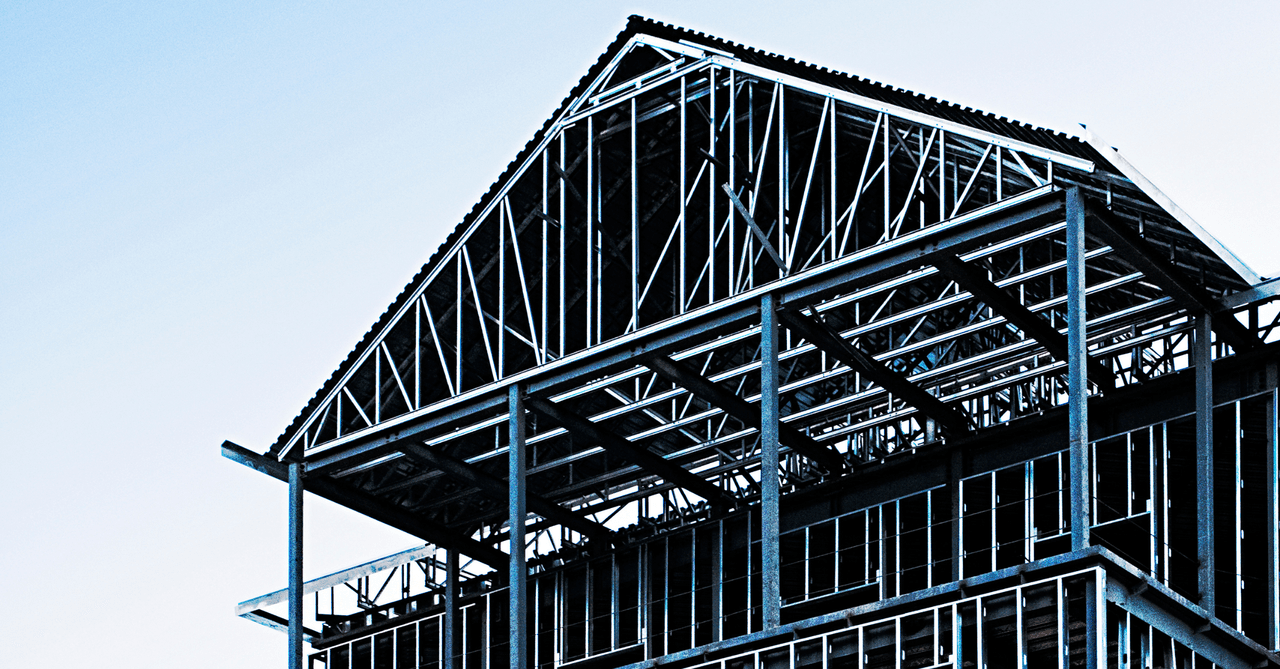

What Is Steel Framing Used For?

Source: Canva

Steel framing refers to a type of framing whose structural organization mirrors that of timber framing. As such, steel framing is also composed of the following:

Trusses

Purlins

Beams

Columns

Lintels (window/door headers)

Bracing

Studs

Plates

Once erected, steel framing is typically covered with metal cladding.

Structure and Components

Structurally speaking, the steel trusses or portal frames used are the same as those employed when building timber framing. They can be:

Single-sloped

Double-pitched

Gambrel-like

Moreover, steel framing features a distinctive structural shape: curved rafter portal frames. This characteristic allows for building structures akin to timber framing while exceeding its structural constraints.

To achieve said shape, steel frames are made with the following:

H beams (wide flange), vertically or horizontally installed

I-beams, installed horizontally to withstand heavy loads

T-bars or beams used as bracing

Z purlins for small structures (spanning under 8 feet)

What Are the Key Features of Steel-Framed Buildings?

The properties specific to steel can be divided into two categories:

Structure-insensitive

Structure-sensitive

Structure-Insensitive Properties

Structure-insensitive properties are directly influenced by steel’s atomic properties—iron and carbon alloy.

For example, when it comes to metal’s tensile strength, it’s a property that’s structure-insensitive. It can be defined by Young’s Modulus, which is tensile stress divided by tensile strain. Since it’s a structure-insensitive property, it remains constant no matter the metal’s composition.

Another aspect related to Young’s Modulus is the modulus of elasticity. It refers to the energy stored in metal that can later be released, which is particularly relevant when it comes to suspension bridges if a cable were to fail.

Structure-Sensitive Properties

These properties depend on the building’s structure and include lateral and vertical force resistance. A steel frame’s capacity to withstand such forces depends on the metal’s bending stiffness and the quality of the connectors used within its makeup.

Reinforced rafters will increase the steel framing’s resistance to lateral and vertical forces.

Why Use Steel Framing Instead of Wood for Your House?

Source: Canva

Because steel framing allows for the following:

Space gain

More design freedom

Prefabrication

Space Gain

Using steel framing is particularly sought-after in the following sectors:

Industrial

Import-export (storage)

Agricultural

Retail

Why is that? Because the above-mentioned sectors struggle with the same constraint: lack of space. And, space is exactly what streel framing brings to the table.

Indeed, even though this type of framing meets the same principles as timber framing (trusses, spans, headers, etc.), it still differs from it given the possibility of building braceless portal frames.

Portal frames are continuous steel-framed structures that correspond to timber-framing roof trusses.

These can be built with beams spanning 131 feet (40 metres), which is something that can’t be done with wood.

Design Freedom

You might not know this, but steel framing allows architects considerable design freedom.

Steel framing is responsible for buildings like the Chrysler Building in New York, King’s Cross St. Pancras tube station in London, and the Eiffel Tower in Paris.

These three prominent landmarks showcase the boundless opportunities made available through steel framing.

Prefabricated

Most steel framing is built in manufacturing plants and later delivered to jobsites. As such, it’s ready for on-site assembly.

The only downside is its complexity. As such, carrying out a hassle-free assembly, devoid of constraints as previously mentioned, hinges on the following:

Cladding

Roofing

Weather

And more

Its assembly must also take into account thermal expansion. This is especially important when installing the underlayment. That way, all the bolts and brackets are safely embedded, preventing the fasteners from puncturing holes into the sheet metal, as it may occur on account of thermal expansion.

In a nutshell, one has to consider all forces (weight of material, wind factor, etc.) imposed on the steel structure. Timber framing is no different.

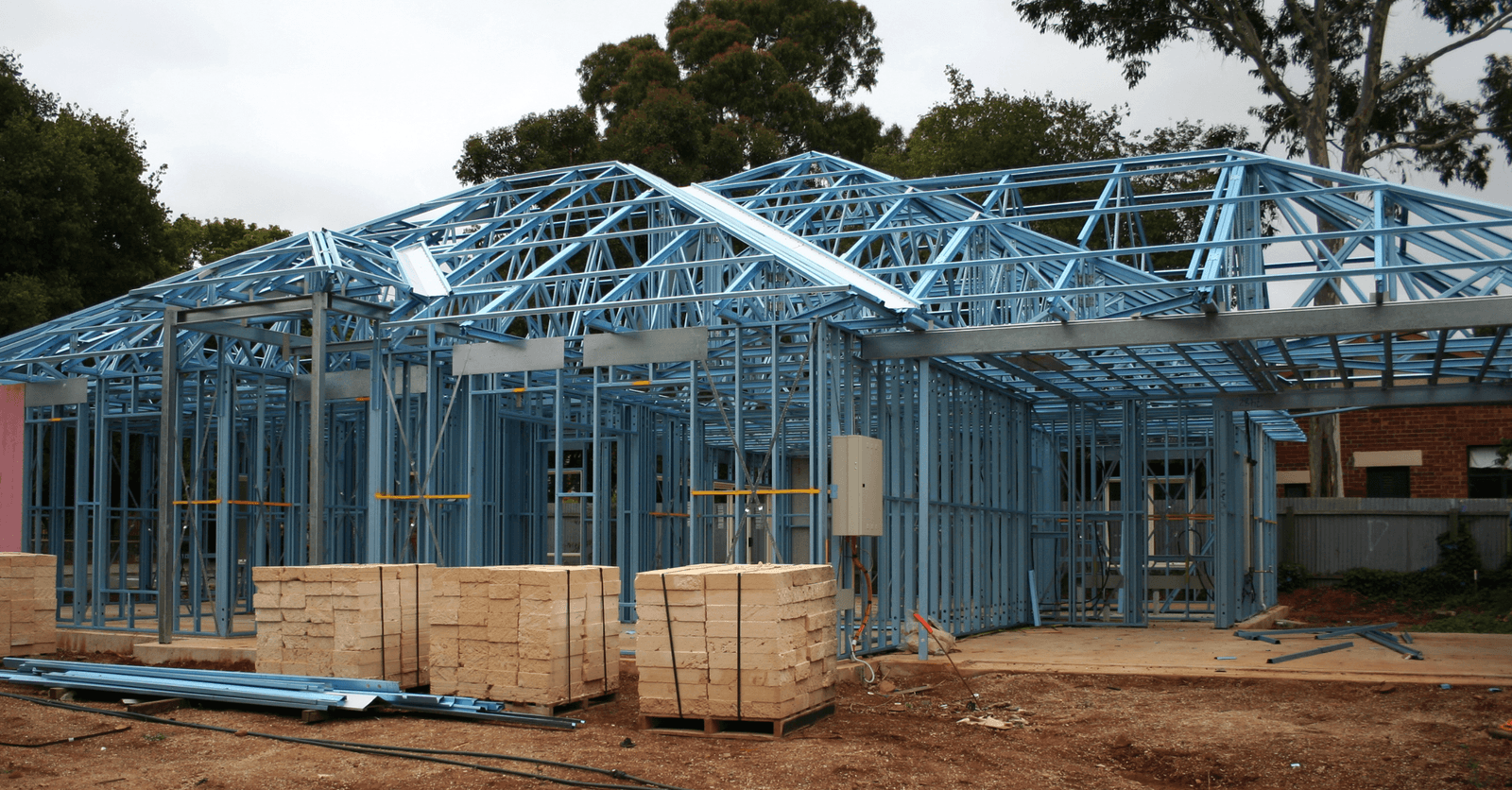

How to Build a Steel-Framed Home

Source: Canva

If you’re looking to throw yourself into a steel framing building project, whip out your calculator now, and stick to the guidelines detailed below.

Step 1: Assess the stresses

To build a sturdy steel frame, you first have to accurately assess the structural stresses the structure will have to uphold. Measuring the stresses imposed will help you determine the potential shapes your structure will assume over time.

We already mentioned Young’s Modulus. Moreover, using the Newmark or Cranston method, uniaxial and biaxial flexion calculations and the structure’s load-bearing capacity should be accounted for, too.

Step 2: Have the frame built

Once everything’s been thought through, calculated, corrected, and managed, you can proceed with the frame’s manufacturing process.

The steel frame’s parts will be delivered directly to your worksite. All that’s left is to assemble the structure itself. However, if you miscalculated anything, and are hoping to make some changes on-site, you’ll have to hire a ferrous metal worker.

Step 3: Assemble metal studs

If you’ve already assembled a timber frame, you can cut the assembly time by 30%, as steel framing is faster to put together.

How to Insulate Metal Roofing

Source: Canva

You can add two different types of insulation to your steel framing. First, there’s thermal insulation, which is a must-have for all Canadian homes. Second, is acoustic insulation, which is a worthwhile add-on.

The latter will limit potential noise from the steel framing expanding, which is amplified by its echoing properties.

Thermal Insulation

Thermal insulation serves the same purpose as insulation installed beneath a wood frame. Steel framing is compatible with:

Glass wool (panel or roll)

Cellulose foam (spray)

Expanded polystyrene (EPS)

Polyurethane foam (spray)

Rockwool (spray)

Soundproofing

The best course of action is to plan for soundproofing ahead of the construction, and the reasoning behind that is quite simple. Once the frame and roof are installed, adding insulation would mean working backwards, and removing the roof.

If the roof is already installed, the soundproofing material can be fitted over the rafters. Otherwise, when building the frame, install the insulation on top of the sheathing.

If your attic space is left unused, install the insulation directly on the floor or spray it into the room.

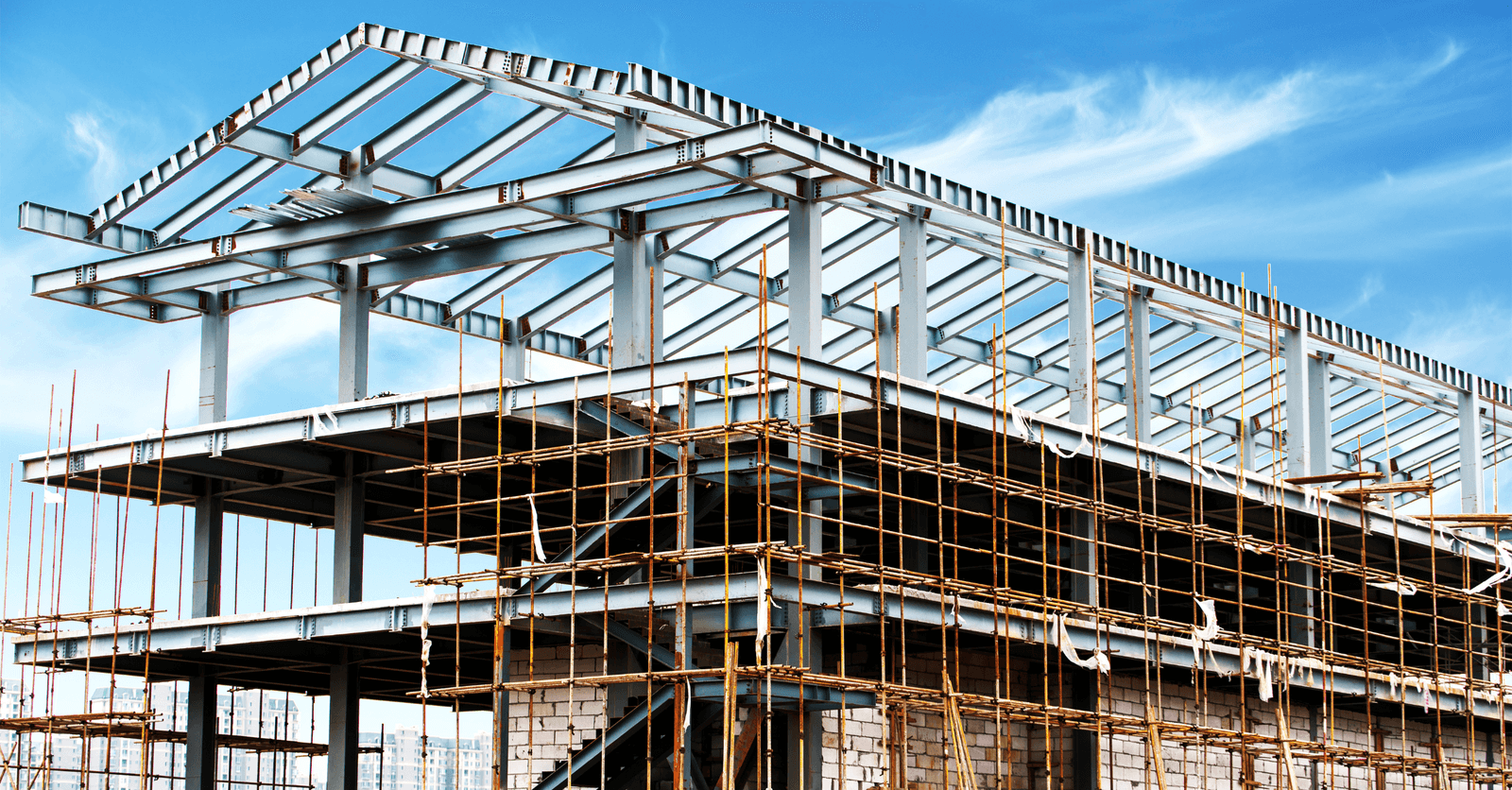

Steel Framing: Is It Cheaper than Wood?

Source: Canva

At first glance, steel framing seems to come out on top on account of the following:

Lighter

More cost-effective

More resistant

Easier to maintain

Lightweight

Steel studs are lighter than traditional wood framing members. As a result, not only are they easier to handle on-site, but their cladding and roofing load-bearing capacity is also greater, making for a high-quality alternative.

Cost-Effective

The savings made when purchasing a steel frame instead of a timber one is 10%. This is only on average as said percentage can dip to 8% or skyrocket to 15%.

Resistant

Typically, laminated steel is used to make steel framing. Said material is especially resilient and exceeds wood's flexion strength.

Easy to Maintain

Steel isn’t subject to fungi growth or insect infestation, making it an ideal material for building a house’s frame. Once installed, it requires no particular treatment or maintenance.

However, the latter no longer applies in the case of corrosion. You'll be witnessing, first-hand, the downsides of steel framing should the structural steel corrode.

Downsides of Steel Framing

Source: Canva

If you’re worried about your frame rusting, or having been wrongly assembled by the hired builders, then opting for wood framing is your best option. The latter is more commonly used, therefore, workers are more familiar and experienced with its building process.

Steel Framing and Rust

As previously mentioned, if steel-framed walls are exposed to moisture, they will corrode. As such, note that the frame of your roof is as exposed to the humidity outside (resulting from condensation) as the moisture build-up inside (breathing, cooking, showering, etc.).

To fight off corrosion, installing the following components over a steel frame, inside the structure itself, comes highly recommended:

Rain barrier

Vapour control layer (VCL)

Controlled mechanical ventilation (VMC)

In any case, opt for a frame made with galvanized steel. This protective coating allows the metal to withstand corrosion.

Yet, corrosion isn’t the only downside of steel…

Technical Side

To guarantee high performance, a steel-framed structure must be particularly well-engineered. Take metal roofing, for example. When installed on a low-slope, wind-exposed roof, rattling noises can resonate throughout the building.

This is particularly relevant when:

The supporting axes are too far apart

There’s a draft in the air gap

There isn’t a separating layer between the sheathing and battens

The wrong material (and thickness) was used

Cracking Caused by Thermal Expansion

Metal tends to expand at high temperatures. As a result, it can make distinctive noises throughout the day, depending on the temperature outside, and if the sheet metal is:

Installed incorrectly (too close to one another)

Too rigid

Clamped onto the steel framing

This occurrence is all the more likely given that steel (and most metals) resonate.

Fire vs. Steel: What Is the Outcome?

The weak structural strength of steel is often highlighted as being one of the main drawbacks of metal roofing. And, compared to the latter, wooden roofs are more heat-resistant.

However, should you have to deal with a house fire, the state of your steel roof won’t be your primary concern.

How Much Does Steel Framing Cost?

Source: Canva

Galvanized steel framing costs between $10–$25/sq.ft. Given that your house will be protected for at least 50 years, priced like that, it makes for quite a worthwhile investment.

For example, here’s a rundown of the structural components used to make steel framing along along with their costs:

Wind brace, 25 gauge, 11.25 ft.: $21

Resilient channel for roof: $10

Corner bead, 10 ft. long X 1 ¼ in. long: $5

U channel, 18 gauge, 1 ½ X 12 ft.: $19

L moulding, 10 ft.: $8

J trim, 10 ft. long X ⅝ in.: $8

Framing stud, 2 ½ in. X 12 ft.: $11

Steel stud, 25 gauge, 3 ⅝ in. X 12 ft.: $16

For more information about framing materials and costs, check out our Financial Guide for Structural Framing.

FAQ

What is cold-formed steel framing?

Cold-formed steel (CFS) framing consists of using quality sheet steel that is shaped into C-sections, as well as other shapes, by rolling and pressing it at room temperature, rather than heating it. It has a high strength-to-weight ratio, making for strong yet lightweight steel framing.

What is light-gauge steel framing?

Light-gauge steel framing is commonly used in home building, where builders utilize thin, lightweight steel components to create structural elements. This type of framing is known for its unique design, offering flexibility and precision in creating strong, durable walls for residential structures. Light-gauge steel is favoured for its strength-to-weight ratio, ease of installation, and rot resistance, making it an appealing option for modern home construction.

Do you have a framing renovation project coming up? Check out our House Framing Handy Reference Guide to Success.

Looking for something else?

Related articles

The latest industry news, interviews, technologies, and resources.

Editorial Team

•08 Nov 2023

When a roof is damaged, it can have significant repercussions on the home, the biggest being water leaks. Water leaks can have devastating effects on the state of your home because the damage can spread as easily as water flows.

Editorial Team

•08 Nov 2023

Given the significant damage iron ochre can cause, it definitely poses a substantial threat. This corrosive iron substance demands particular concern, whether for homeowners already contending with its adverse consequences or for prospective buyers apprehensive about its potential impact. In any case, here's all of the relevant information you need about the tell-tale signs of iron ochre.

Editorial Team

•18 Apr 2024

Have you noticed the presence of traces of humidity in your crawl space? You're right to wince because a buildup of moisture is never good news.

Editorial Team

•09 Nov 2024

Bathrooms hold a special place when it comes to home improvement projects. Why consider a bathroom renovation? What are the advantages, from both a functional and aesthetic perspective? In this article, we’ll explore the reasons pushing homeowners to remodel their bathrooms. Discover how a renovation can transform your space into a literal slice of heaven, increasing the value of your property, and optimizing the space’s user-friendliness. We’ll also look at the potential challenges associated with costs, renovation timelines, and their impact on one’s daily routine. Ready to give your bathroom a long-awaited facelift? Let’s delve in!

Editorial Team

•31 Jan 2025

While artesian wells are often the preferred choice for a cottage’s water supply, they have a slew of noteworthy yet overlooked features.