How to Choose the Best Caulks and Sealants

By Editorial Team

Updated on July 23, 2025

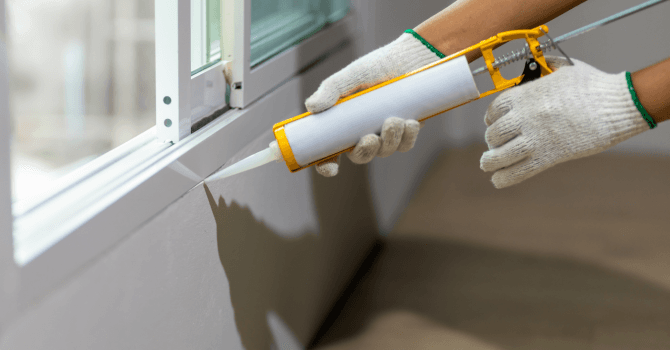

Caulking can be defined as the process of sealing or filling gaps, done to prevent leaks and drafts. To do so, numerous caulking or weatherizing products are developed and often sold in retail stores as caulks, sealants, or mastics. They’re made with butyl, silicone, urethane, acrylic, or even latex, and said material diversity makes it all the more difficult to choose the right product.

To help you out—and make choosing the best caulking product based on your needs an easier ordeal—we’ve put together a guide, allowing you to better understand what a sealant is and the specific characteristics and properties it should have. Whether you're sealing around plumbing fixtures or tackling larger gaps in exterior projects, the right product can make a huge difference.

What Key Features Should You Look for in a Sealant?

Source: Canva

Caulking products typically have four basic characteristics. They must:

Fill gaps

Create an airtight and waterproof seal

Be long-lasting

Have a strong hold

As such, a sealant is, first and foremost, a product to fill all irregularities between two surfaces. Unlike more traditional materials, such as glass fibre, for example, caulks aren’t porous. Therefore, its airtightness isn’t connected to compression force.

However, not all sealants are alike. Their composition will affect their liquid-retention capacity. For example, while outdoor silicone caulks are effective products when it comes to withstanding water in its liquid form, they’re a lot more limited when dealing with vapour. Over time, if the wrong caulk is used in an area with high exposure to moisture, it may lead to water damage or mildew growth.

A proper sealant should also:

Adapt to shifting gap sizes caused by temperature changes

Withstand compression and tension forces greater than 50%

Resist heat, rain, and direct sunlight

To achieve a performance equal to that mentioned above, caulking products must have a slew of properties that support durable seals.

What Properties Should a Decent Sealant Have?

Source: Canva

1. Curing Properties of Sealant

There are three important elements to consider when it comes to the curing process of any given caulking product.

Sealants and caulking products do require a certain amount of time to cure. Throughout this period, the joint has to remain fixed, otherwise the airtight seal may be compromised. Therefore, curing time is definitely something to consider. Using a proper caulking gun during application also helps maintain smooth, straight lines that promote a consistent bond.

The hardening depth is directly correlated to the amount of moisture in the air. Certain urethane-, silicone-, or polysulfide-based products need several days, sometimes even weeks, to cure through.

Shrinking is linked to product composition, meaning sealants that shrink the least are those made with a single material, such as silicone, plastisol, urethane, or even polysulfide.

On the other hand, solvent- or water-based products are particularly prone to shrinkage as a part of these components are likely to evaporate during curing. Be sure to read the product label to avoid selecting old caulk or outdated stock.

2. Physical Properties of Sealants

Sealants have a lot of physical properties, some of which are:

Hardness

Consistency

Decent elasticity (modulus)

Compression resistance

Movement capability

Durability

Exposure resistance

A sealant must have a hardness measured between 15–70 on the Shore Hardness Scale. If, over time, the product hardens further, it’s a telltale sign of deterioration.

The flexibility of caulks is determined by its modulus (elasticity), which refers to its ability to accommodate shifts and movements in the filled space. This allows it to adjust without exerting strain on the applied surfaces, especially in high-use areas like those near plumbing fixtures.

Compression resistance refers to the force the sealant is designed to withstand before breaking down. On the other hand, a sealant must also be capable of reverting back to its initial shape once the pressure is alleviated.

Stress relaxation is the state in which the caulk must withstand tension, allowing it to revert to a more stable state despite said stress. Not all sealants can do so and end up deteriorating.

Lastly, creep—deformation—is the caulking product’s capacity to maintain a stable state despite increasing tension. This is essential for all sealants used to support structural loads and ensure long-lasting, durable seals.

3. Thermal Properties of Sealants

Outdoor caulks are elastomeric. As such, these products are prone to weather damage. When it’s cold outside, it stiffens; when it’s hot, it softens. Note that all outdoor sealants used for household purposes are weatherproof, meaning those used to seal around your windows and doors, for example.

When in doubt, here's a list of products with their corresponding resistance levels:

Butyl and acrylic: 80°C (over 175°F)

Polysulfide and urethane: 100–150°C (212–300°F)

Anaerobic: 150–200°C (300–390°F)

Silicone: 200–300°C (390–570°F)

Therefore, sealants will last, even when sun-exposed, through the summer, and in the middle of a heat wave.

4. UV Resistance

The good news is that most household outdoor sealants are made with silicone. Indeed, silicone is naturally resistant to UV radiation. However, other caulks, such as urethane-based products, must be treated with a UV absorber or inhibitor.

As a result, if you were to opt for a polyurethane-based sealant, read over its manufacturing label to ensure it’s made with a UV absorber or inhibitor, labelled as such: UV-328. This is especially important when working on exterior projects exposed to direct sunlight.

5. Adherence

The sealant must stick to the surfaces onto which it’s applied. A lack of adherence can lead to faulty seals, resulting in a build-up of humidity between the sealant and substrate. Over time, corrosion will settle in.

Here’s where a primer can be handy. Note that a sealant sticks to surfaces on account of its molecular composition. Some molecules are compatible with the sealant, while others are with the surface onto which it’s applied.

Therefore, some primers will bridge the gap between the sealant and the surface. Should you be looking, note that silane primers are amongst these. Selecting the right product with proper compatibility ensures fewer issues over time and lowers your energy bills by reducing air leaks.

What Are the Best Caulkings? Top Sealants: Advantages and Prices

Source: Canva

Silicone Caulking

Let’s just say that the sealant with the most advantages is the silicone sealant, as it meets all the characteristics mentioned above. However, it typically can’t be painted and has a strong odour. Still, its ability to resist mildew growth and temperature changes makes it a great choice for kitchens and bathrooms.

A 10.1 oz tube of silicone sealant costs roughly $7.

Latex-Based Caulking

On the other hand, latex-based caulking products, also known as acrylic latex caulks, barely smell and can be painted. If you recall what we mentioned earlier about solvent- or water-based caulks, then you know that latex is prone to shrinking. As such, it can solely be used indoors, given that it’s not heat- or UV-resistant.

This type of sealant is especially cost-effective; a single, 10.1 oz tube retails for less than $3.

Polyurethane Caulking

Polyurethane sealants are also known as quality products. They’re easy to apply on intended surfaces compared to silicone and are retailed in an array of colours. Therefore, there’s no need to paint over the material. Polyurethane sealants also adhere better to wood than silicone caulks. Moreover, texture sealants are also available, making for a more subtle application.

A 10.1 oz tube of urethane sealant retails for about $12.

Sealing Outdoors: What's the Best Type of Caulking for Exterior Use?

Source: Canva

Silicone is, without a doubt, the best sealant sold on the market, as it meets all the properties detailed, such as:

Flexible

Weatherproof

UV-resistant

Compression and tension force resistance

Paintable

As we already detailed, when it comes to polyurethane sealants, it all depends on product composition. If it's UV-resistant, it can be used to caulk around exterior window frames. Just be sure to select a product in the right colour to match your surfaces for a seamless look.

Check the manufacturer’s label to ensure its characteristics are compliant with Standard ASTM C920, as well as Class 25. The latter simply indicates that the product’s flexibility, tension properties, and durability were laboratory-tested.

FAQ

What is the best caulking for bathrooms and showers?

The best type of sealant to use in a shower is silicone. Given its flexibility, resistance to high temperature changes, and durability against high moisture levels, it's the best choice for a hot and humid environment.

What is the best caulking for windows?

While silicone is still a great option, a silicone-latex blend caulk is the best choice. Not only does it offer the benefits of silicone sealants, but it can be painted as well to match the colour of your house!

What is the difference between caulking and silicone?

"Caulking" is a general term for materials used to seal gaps or joints in construction, such as between tiles, windows, or fixtures. "Silicone," on the other hand, refers to a specific type of caulking product made from silicone compounds. Silicone caulking is known for its flexibility, durability, and resistance to moisture and temperature changes, making it ideal for kitchens, bathrooms, and exterior projects.

Looking for something else?

Related articles

The latest industry news, interviews, technologies, and resources.

Christine Simard

•08 Nov 2023

Whether you live in a small apartment or a large family home, the organization of your space is the key to keeping your household neat and well kept together.

Editorial Team

•01 Aug 2024

If you noticed significant changes in your house and detected a structural shift over time, the odds are that the stability of your foundation has been weakened. By that, we mean that the foundation may have collapsed. The latter may be the result of the soil, which can’t adequately bear the load of the structure, the presence of clay soil, a water table, or full-grown trees, whose roots have reached the outer walls of the foundation.

Editorial Team

•18 Jun 2024

While traditional, wood-burning stoves have been flagged by the City of Montréal for their high levels of pollution, the current by-law regarding the use of less pollutant models is also to come under review. As such, in 2020, all solid fuel-burning appliances were banned, except for pellet stoves. The latter are still tolerated, even though they can only be used during smog-free periods.

Editorial Team

•18 Apr 2024

As technology continues to advance, there are more advanced and environmentally-friendly ways to heat your home during those chilly months. From the wood burning stove to electric and gas heating methods, nothing is perfect. It’s a familiar struggle in winter to want to trap the heat in your home while keeping utility costs down. But, does a heating system exist that is efficient enough to keep fresh air in the home while maintaining a comforting heat level? Enter the heat recovery ventilator!

Editorial Team

•19 Nov 2025

La gestion de CNESST (Commission des normes, de l’équité, de la santé et de la sécurité du travail) is often seen as a simple administrative formality, focused on the annual payroll declaration. However, for SMEs in the construction sector, effective CNESST management goes far beyond this obligation. Optimizing health and safety on worksites, anticipating risks, and keeping up with regulatory changes are essential to controlling costs, protecting workers, and ensuring the long-term sustainability of the business. To fully benefit from these practices and avoid common pitfalls, it is important to lay a strong foundation for your company from the outset.