Concrete panels are durable, cost-effective, and viable options for both indoor and outdoor walls. Their list of attributes doesn’t end here: they're also easy to install, especially aesthetic-looking, thermal insulators, and soundproof. We’ll delve into why and how these panels should be installed.

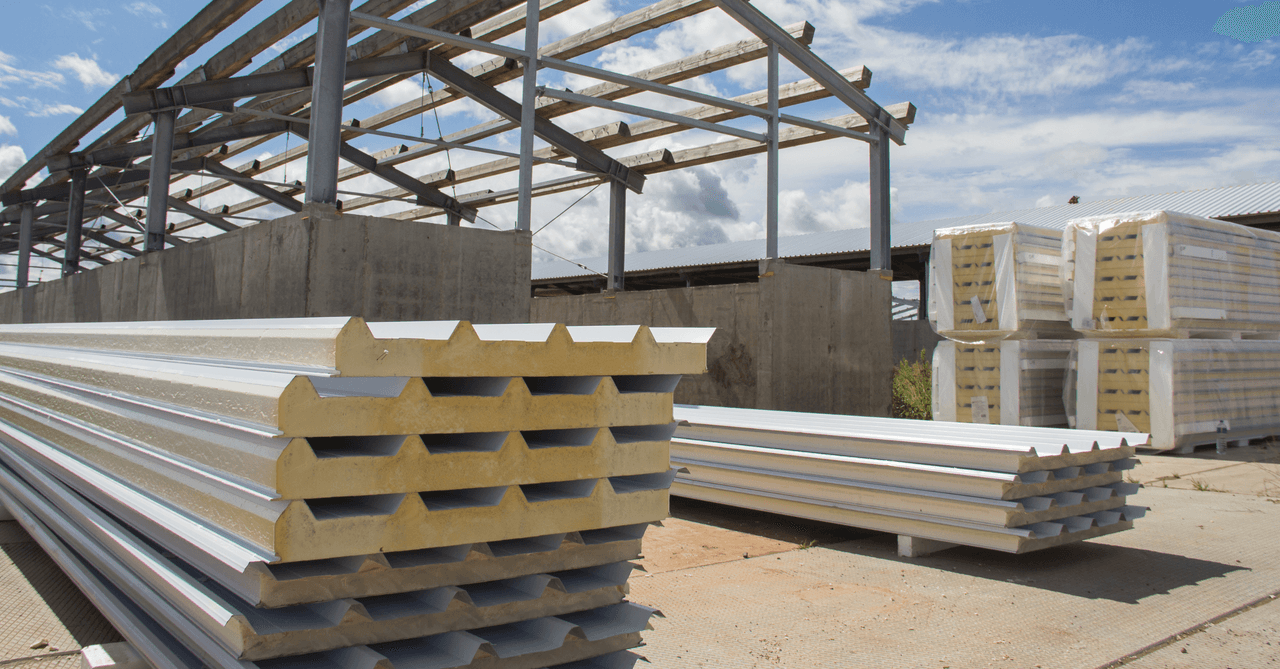

Characteristics of Lightweight Concrete Outdoor Wall Panels

Source: Canva

Concrete panels are considered lightweight when their density is between 90 to 115 lb/ft³, as opposed to regular concrete’s 140 to 150 lb/ft³. As such, they weigh roughly forty pounds (20 to 30 kilos) apiece and have:

low thermal conductivity;

high thermal resistance;

reduced likelihood of shrinkage;

increased ability to withstand rotting.

Variations are made using different types of aggregates. With lightweight concrete, it can be:

Slate

Ash

Schist

Pumice

Clay

Perlite

Introducing New Aggregates

Over the last few years, materials from agricultural waste have made their way into the manufacturing process of lightweight concrete panels, OPS (oil palm shell) concrete being one of them.

Furthermore, innovations aren’t curbed yet, as experiments are carried out to manufacture concrete panels sourced from the slag generated by gasification processes and fly ash issued from petrochemical incineration.

These products, stemming from an integrated gasification combined cycle (IGCC), are used to produce glass-ceramic, and with lightweight concrete, exhibit compressive strength exceeding the requirements established by the international standards organization ASTM International (formerly known as American Society for Testing and Materials).

PCSP

Also available are PCSPs—precast concrete sandwich panels—which are rightfully named for their 3 layers (concrete - insulation - concrete), and have valuable characteristics:

withstand compression load;

lightweight;

energy efficient;

durable, safe, and comfortable.

Specifically, it’s a mix of 3 mm expanded polystyrene beads and cement, to achieve a density equalling 9 kN/m³.

Why is lightweight concrete cheaper than regular concrete?

Simply because regular concrete, being heavier than its lightweight counterpart, requires rebar (structural reinforcements), like framing, steel beams, etc. As such, the total cost of a project will be higher using regular concrete as opposed to lightweight concrete.

Easily find clients starting today

Get started today and connect with the projects that suit you best!

How to Install Fibre Cement Panels

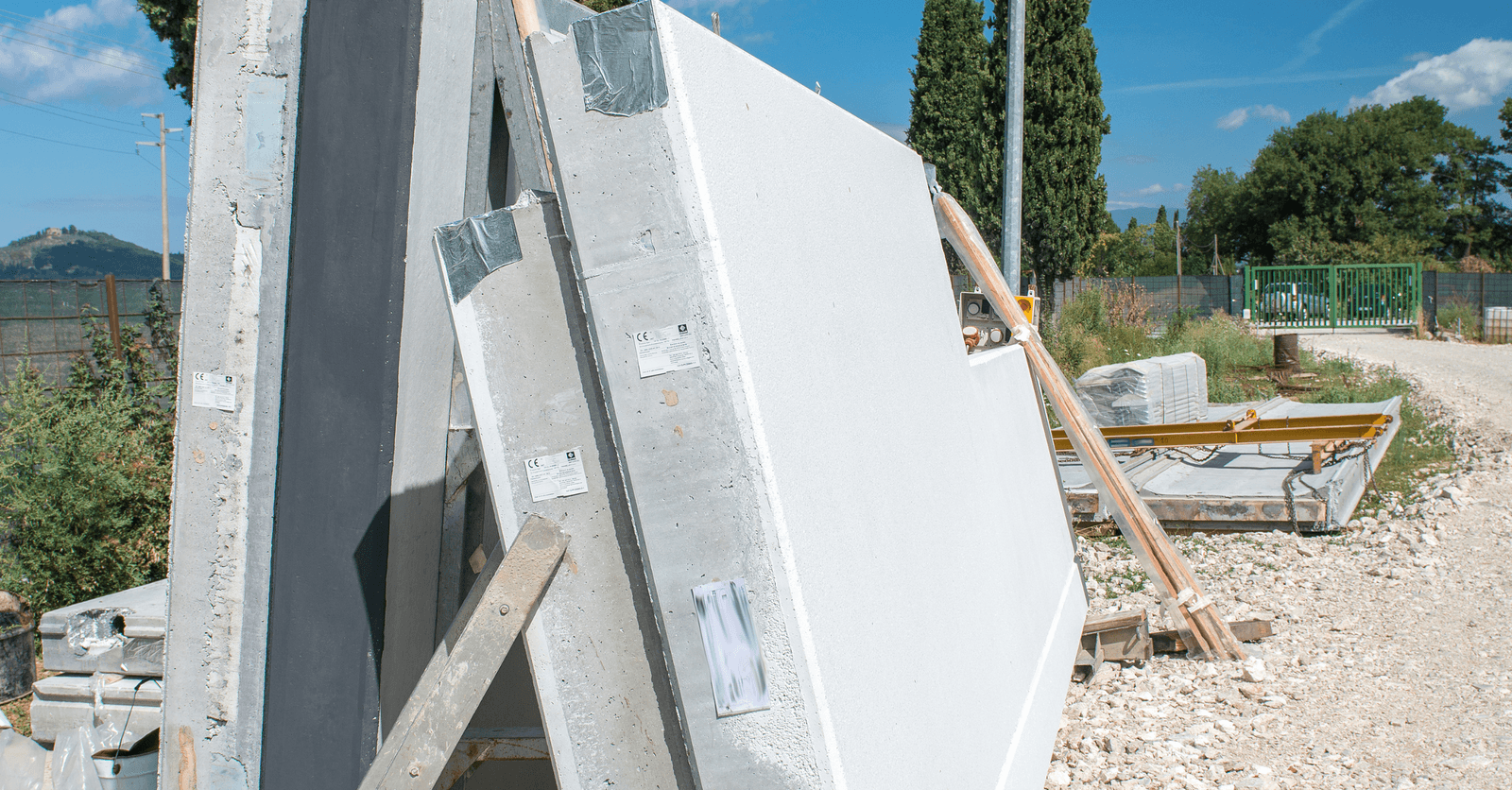

Source: Canva

Fibre cement panels can just as well be installed inside as outside since they’re fit for roofing. They’re used as a thermal barrier coating, and reinforced with a fibreglass mesh to withstand UV rays.

Here’s a 9-step guide for installing fibre cement indoor wall panels:

Step 1: Gather materials

Here’s everything you need to secure fibre cement wall panels:

Low-expansion construction foam

Caulking gun

Electric drill

Hammer

Compressor with 16-gauge nailer

1 ¾ inch finishing nails

Wood shims

Laser level or 4-inch line level

Tape measure

Grinder or mechanical saw with a diamond blade

Step 2: Inspect plywood

Once installed, lightweight concrete is just as resilient as plywood. However, if the plywood isn’t properly installed, or isn’t sturdy enough, the lightweight concrete panels will mirror the former’s characteristics.

Step 3: Unbox and store panels

Upon delivery, your panels will be boxed in protective packaging. To remove the panels from their packaging, lay the panels sideways, vertically on their edge. If laid horizontally, they risk breaking.

The same concept applies during transportation. Always transport concrete panels vertically rather than horizontally, to prevent breakage.

Step 4: Mark the wall

To install concrete panels, always start with the first row, meaning at the bottom of the wall. Make a mark to indicate the wall’s midpoint as well as to indicate the height of the first concrete panel.

Based on the height of the concrete panel, you can then set your laser level or use your line level.

Step 5: Prepare panels

Once you’re certain of where the first concrete panel should be secured (centre fit at the bottom of the wall), you can go ahead and apply the low-expansion construction foam on the back of the panel.

You can apply the product in a sinuous-like wave pattern, from top to bottom, over the panel’s entire back surface.

Step 6: Wedge the panel

Should you not want the panel to sit directly on the floor, especially if the latter isn’t level, you can wedge a wood shim beneath it. Otherwise, you can simply hold it in place for a few seconds until it adheres to the wall.

You can then nail them in place using a nail gun. The concrete’s texture will conceal the nails.

Step 7: Cut panels accordingly

The last panel in each row will most likely need to be cut. To do so, you can use a grinder or mechanical saw fitted with a diamond blade.

Step 8: Check level and thickness

This is a crucial step. The first row must be completely level, otherwise, the subsequent rows will also be crooked.

Once the panels have all been installed, you may notice a discrepancy between one panel to the next. Should this be the case, use a wood shim to adjust the panels accordingly. This will allow you to have a perfectly flat and levelled wall.

You can also drive a screw into a panel in question and use it as an anchor point to then pull the concrete panel toward you to adjust it accordingly.

Keep in mind that you only have about 5 to 10 minutes to make any necessary adjustments before the adhesive cures.

Step 9: Caulk the edges

Caulk the panels’ edges with an adhesive, while using a trimming tool to apply the silicone. You can remove any excess product using a putty knife.

Lastly, sand the surface of every concrete panel with a fine-grit sandpaper. Doing so will effectively remove any and all fingerprints, as well as accumulated dirt resulting from the installation.

Types of Panels

Source: Canva

Concrete panels have made their way into all construction-related fields:

Architecture

Interior use

Décor

Fireplace walls

Flooring

Architecture

Lightweight panels are available in an array of colours and are more often than not the sought-after choice amongst architects. So much so that it resulted in the inception of a new trend: photo-engraved façades. This involves using patterned concrete to depict a grooved image. When it comes to pre-fabricated concrete, the image is moulded and positioned at the bottom of a mould.

There are two other techniques:

Graphic Concrete

Béton picturalⓇ

Both methods are distinct. The first method involves using a retarder to delay the concrete’s curing process in certain areas, thereby allowing aggregates to show through. This is achieved using a special membrane with a retarder. On the other hand, the second technique entails digitally printing an image onto a concrete slab.

Therefore, concrete panels are the perfect canvas for a new, vector graphic-based architectural art.

For Indoor Use

Walls aren’t the sole surface to accommodate concrete panels. They’ve permeated every corner of the home:

Floors

Behind fireplaces

Bathrooms

etc.

They’re just as used in single-family homes as in administrative and commercial buildings.

Decorative Concrete

Although lightweight concrete panels are designed to withstand loads, they’re, first and foremost, thought of as decorative pieces when used indoors in their ultra-lightweight versions, weighing roughly forty pounds (20 to 30 kilograms).

Concrete panels are available in various shades of grey and are particularly valued for instilling modern-looking interior designs. They exude a sophisticated ambience that combines elegance and charm.

For Fireplace Walls

If you’re looking for fireplace wall cladding, fibre cement panels are perfect for that, given that they can be positioned around and behind fireplaces.

Panels are retailed as 4-, 8-, or 10-feet high boards, with thicknesses ranging from ¼ to ½ inches, as provided by manufacturers.

As Flooring

Concrete panels can be glued onto subflooring, whether the latter is made of plywood or OSB. Concrete panels and subfloors are adhered together by mortar or using an adhesive.

When proceeding with installation, avoid overlapping the panels’ joints with those of the subfloor.

Get 3 quotes for your concrete-related project

RenoQuotes.com can help you get quotes from a general contractor. By submitting your project, you'll be connected to top-rated contractors. Fill in the form on the homepage (it only takes a few minutes) and get estimates from trusted professionals.

Dial 1-844 828-1588 to speak with one of our customer service representatives.

Looking for something else?

Related articles

The latest industry news, interviews, technologies, and resources.

Editorial Team

•08 Nov 2023

Whether you’re going about your business quietly or sleeping peacefully. It’s pretty natural to want to feel safe at home. For some of us, this sense of security comes with the need to have an alarm system installed.

Editorial Team

•08 Nov 2023

Who doesn’t love a cool summer breeze on a sizzling summer day? Being able to open and close your windows freely is one of the perks of having them. But of course, the mechanisms for opening and closing windows break occasionally. Window cranks, also known as casement operators, have a spline that slowly wears down from continued use and over time, and will need to be repaired or replaced.

Editorial Team

•04 Feb 2025

Taking the leap and investing several thousand dollars in a renovation comes with its fair share of worries, especially with regard to the contractor hired to manage the project. If you hire the wrong person, you're likely to find yourself amid a serious mistake that will cost you both time and money to make go away.

Cynthia Pigeon

•08 Nov 2023

The cathedral roof (or cathedral ceiling) was first introduced in the 1960s and 1970s. This type of roof is aesthetic and adds a unique flair to any home. The cathedral ceiling accentuates the interior appearance of a home by exposing the slope of the roof. Constantly modernized and revamped, the cathedral roof is most commonly a feature in chalets and country houses.

Amanda Harvey

•08 Nov 2023

When you think about your bathroom, you may not consider it a space with futuristic potential. The possibilities of our world have expanded as a result of technology, and of course, your home is the next logical step when it comes to enhancing your lifestyle.