Roof trusses are an integral part of roof building and renovation processes. They provide structural stability and durability, essential criteria for ensuring long-standing homes. Understanding the basis of roof trusses means making well-informed decisions during the course of your renovation or construction projects.

Check out our website to learn more about roof trusses and get a few tailored pointers along the way. Contact our skilled team to talk over your project and find solutions suited to your needs. We’ve got you covered, each step of the way.

What Is a Roof Truss?

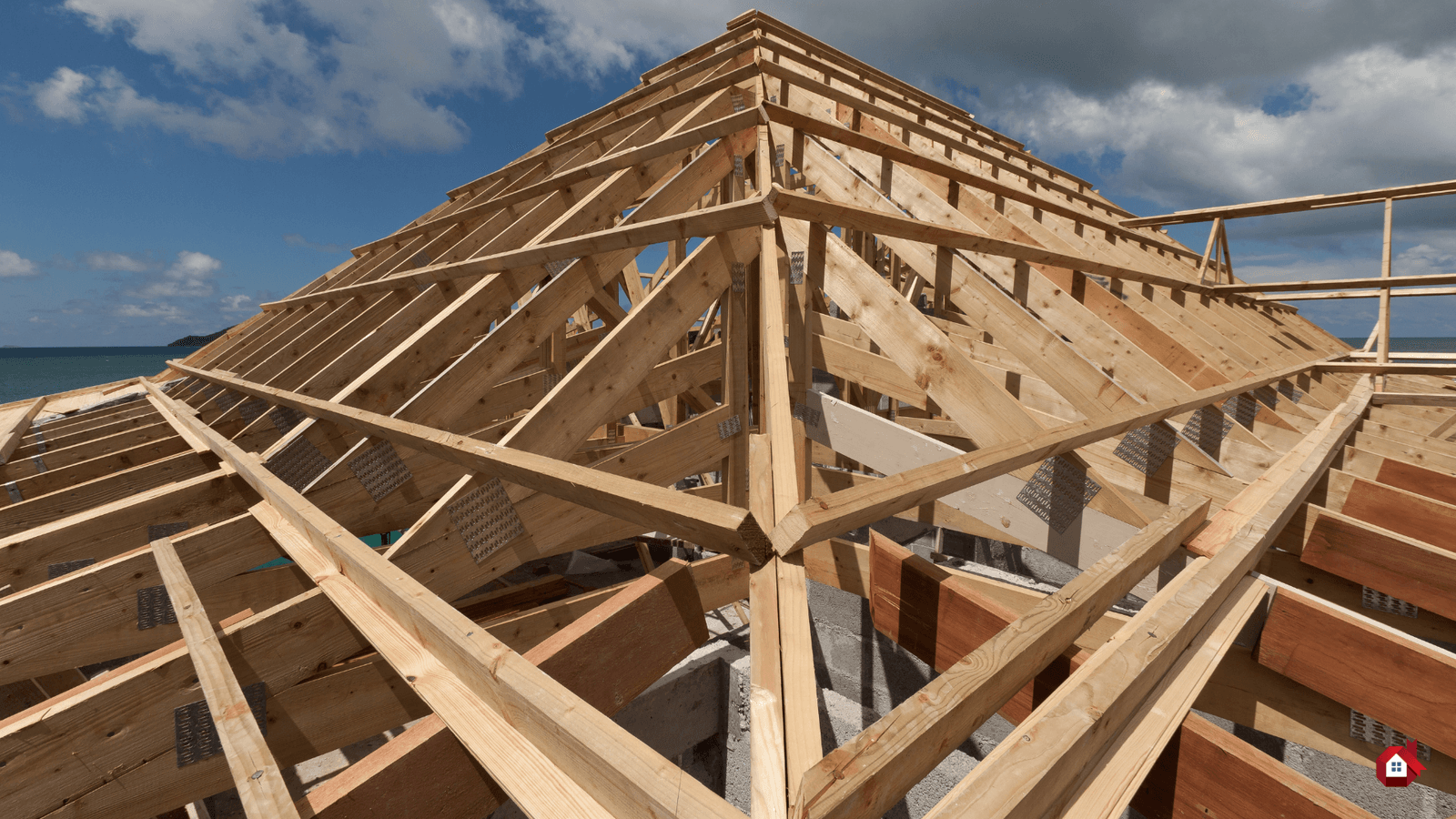

Roof trusses are pre-engineered structures used to uphold a roof; they're either made of timber or steel. Roof trusses are manufactured in factories and delivered straight to worksites, ready to be installed. They’re designed to provide great stability and withstand the roof’s loads. Such structures make creating robust and durable brace systems possible.

Pre-engineered structures are manufactured with top-tier, quality materials and comply with the requirements as detailed in the National Building Code of Canada.

What Is the Difference Between Roof Trusses and Rafters?

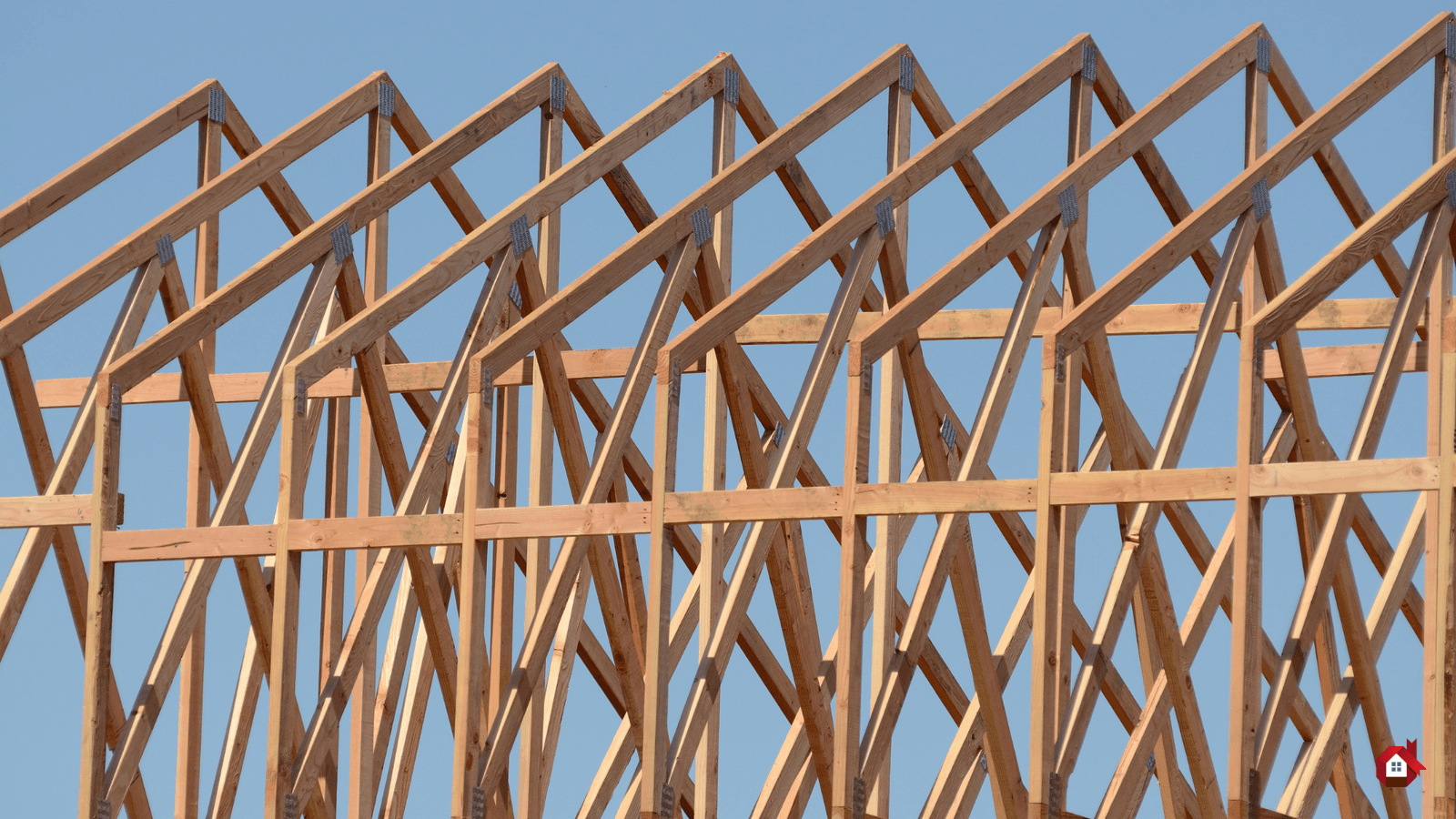

Roof rafters and trusses are two different methods of building roof frames. Rafters are individual timber beams fitted parallel to one another, whereas roof trusses are pre-engineered structures that include several factory-assembled pieces. Trusses allow for a fast-paced and precise installation, reducing labour costs and building time. On the other hand, rafters offer more flexibility in terms of customizable concepts.

Roof trusses don’t call for more load-bearing walls and can be installed in a day or two, whereas installing rafters can take up to a week. Trusses are ideal for large-scale projects, while rafters are better suited for smaller construction projects.

Advantages of Roof Trusses

These structures have several advantages compared to traditional roof-building methods:

Fast-paced and precise construction: Trusses are pre-engineered, making for a fast and accurate installation method.

Reduced labour costs: Prefabrication allows for reduced worksite labour, which, in turn, lowers labour costs.

Better use of space under the roof: Trusses optimize the open space under the roof, making for more interior layout possibilities.

Peace of mind: These structures are designed and manufactured to guarantee maximum stability and durability.

Different Types of Roof Trusses: Understanding Truss Designs and Structures

There are several different versions of said structural element, each distinguished by unique specificities:

Standard: Built for reliability and versatility, it can span up to 10 metres and its triangular shape makes it especially easy to integrate.

Gambrel: Used to build barn-like structures.

Attic: This makes building a habitable space in the attic possible on account of the bottom chord doubling as a floor joist.

Scissor: Used to create a vault-like ceiling.

Cambered: Ideal to create a sense of height with a horizontal beam.

Flat: Used for flat roofs with a slight slope to ensure proper drainage.

Piggyback: Fabricated in two parts for significant vertical spans, assembled on-site.

Monopitch: Forms a right-angled triangle, often used for hangars, sheds, and garages.

How Are Roof Trusses Made?

These structures are pre-engineered in factories according to set specifications, as detailed below:

Material selection: Choosing between the highest quality of timber or steel.

Cutting and assembling: The components are cut and assembled according to detailed plans.

Bracing: Steel connector plates are used to secure the timber in place.

Quality control: Each unit is inspected to ensure every detail complies with the construction industry's standards.

Choosing the Wood

Wood is the most commonly used material to fabricate roof trusses given its natural properties and ease of use. Here are a few other criteria to consider when selecting your timber:

Durability: Wood must be treated to withstand bad weather and insects.

Stability: The wood used must be strong enough to withstand the roof’s loads.

Availability: Choose a type of wood that’s always available to curb costs.

Dimensions

Dimensions do vary based on the project’s specific needs. Roof trusses are manufactured in standard sizes, including 20- to 33-foot spans, with heights that vary based on the truss and the roof’s slope. For example, a standard roof truss can span 26 feet and measure 6.5 feet tall at its midpoint. However, you can also order custom-made structures to better suit the specificities of your worksite.

Assembly

During the manufacturing process of roof trusses, on-site assembly relies on a series of steps:

Worksite preparation: Double-check measurements and prepare the support structure.

Install trusses: Lift and secure the units in place.

Secure connector plates: Use the steel connector plates to secure the timber beams against one another.

Final quality control: Inspect the installation to ensure its structural sturdiness and stability.

Manufactured vs Engineered Trusses

Put simply, a manufactured roof truss is typically pre-built to standardized specifications, while an engineered roof truss is custom-designed to meet specific structural requirements of a building.

What Do They Cost? Prices and More

Costs depend on several factors, most notably size, timber type, and design complexity. Here are a few additional factors to consider:

Size: The bigger the structure, the steeper the price tag.

Material: The choice of wood will affect the overall cost; some options are cheaper than others, and others are more expensive yet longer-lasting.

Complexity: Complex designs are time-consuming and require more materials, which, in turn, spikes costs.

On average, costs can vary between $50 and $200 per unit, based on your project’s specificities.

Why Are Roof Trusses the Right Choice for Your Project?

Roof trusses are an efficient and durable roof-building solution. They bring several advantages to the table, most especially a fast-paced installation, lower costs, and make for better use of the empty space sitting beneath the roof. By understanding the different options made available to you, as well as the different fabrication and assembly steps, you can make an informed decision regarding the structures that best suit your needs and ensure the success of your construction project.

Get 3 renovation quotes for your roofing project

RenoQuotes.com will put you in contact with 3 reliable contractors for your roofing renovation project. Fill in the form on our homepage (it only takes a few minutes), and you will receive quotes from trusted professionals.

Dial 1-844 828-1588 to speak with one of our customer service representatives.

Looking for something else?

Related articles

The latest industry news, interviews, technologies, and resources.

Léa Plourde-Archer

•08 Nov 2023

Doesn't the idea of a rooftop terrace sound lovely? Of course it does and as a result, this project is becoming more and more common. This outdoor area can be turned into a pleasant and unique space for socializing and enjoying the sun.

Editorial Team

•04 Nov 2025

A roof in good condition is essential to protect your home from the elements. Over the years, however, several problems can develop, causing leaks, energy loss, and costly damage. This article lists the most common roofing issues and explains how to detect and repair them.

Paul Riopel

•22 May 2024

Entering the world of subcontracting in Ontario? This article will walk you through the essentials - from gaining relevant work experience, understanding the legalities such as employment status and taxes, to navigating the job market.

Editorial Team

•08 Nov 2023

Often on the blog, we discuss decor and design trends but we usually focus on the home front. This allows our readers to find inspiration to create the perfect layout for their interiors and exteriors. But what about those looking for ideas for their business?

Editorial Team

•08 Nov 2023

Renovating a kitchen can be expensive, and depending on the changes made, your budget can quickly increase. Of course, you don’t have to tear down your cabinets or demolish a wall in order to tastefully renovate and offer your kitchen a new look.