A home or building with a flawless plumbing system is a serious luxury. The repair of these systems and fixtures isn’t carried out by just any individual. Plumbers are in charge of keeping water flowing smoothly. Plumbing is an underrated profession, and the necessity of plumbers in modern-day society is growing more and more significant.

If you’re considering a career in the vast world of plumbing, what's there to know? A plumber needs a wide variety of skills that involve much more than simply unclogging a drain or two. In this article, we’ll go over what it takes to become a professional plumber.

Working in Renovation: Becoming a Plumber

source: unsplash

Education

Moving into the world of professional plumbing will begin with getting a base-level education. This profession requires a high-school diploma or equivalent. When it comes to getting a trade, it’s integral that you have basic reading, writing and math skills down. To work as a professional plumber, it will be necessary for you to have advanced math and science skills. This is because plenty of plumbing work will involve being able to accurately measure and gauge different aspects of water levels.

If you don’t have a diploma or GED and are looking into getting one to pursue this career; we would suggest focusing on the following areas of education, as they’ll be necessary to plumbing:

Metric units of measurement;

Algebra;

Geometry;

Thermodynamics;

Biology.

Not only do these areas require careful attention, but moving forward with a career in plumbing will require a clean record. This includes your driving record, criminal background, and history with substances. For many plumbers, having a license as well as access to a vehicle is a must and thus, a clean driving record is more than necessary. Not only this, but many employers may refuse to work with you if your record isn’t clear.

Training Program

source: unsplash

A clean record and high school diploma are the base-level requirements for moving forward with a plumbing career. Once you have these things, you can start thinking about enrolling in technical courses. Technical plumbing courses will absolutely be required if you’re serious about this career. Depending on the city or municipality you’re living in, you’ll be required to complete a certain number of hours in the classroom as well as a certain number of hours apprenticing in the field.

The specifics of these requirements will greatly depend on where you’re living, so do be sure to look into community college or trade programs as well as professional plumbing unions or associations for all the important information about moving into this area. Here are some expected topics when it comes to finding education on the subject:

Pipe cutting;

Drainage;

Soldering;

Water heating systems;

Ventilation.

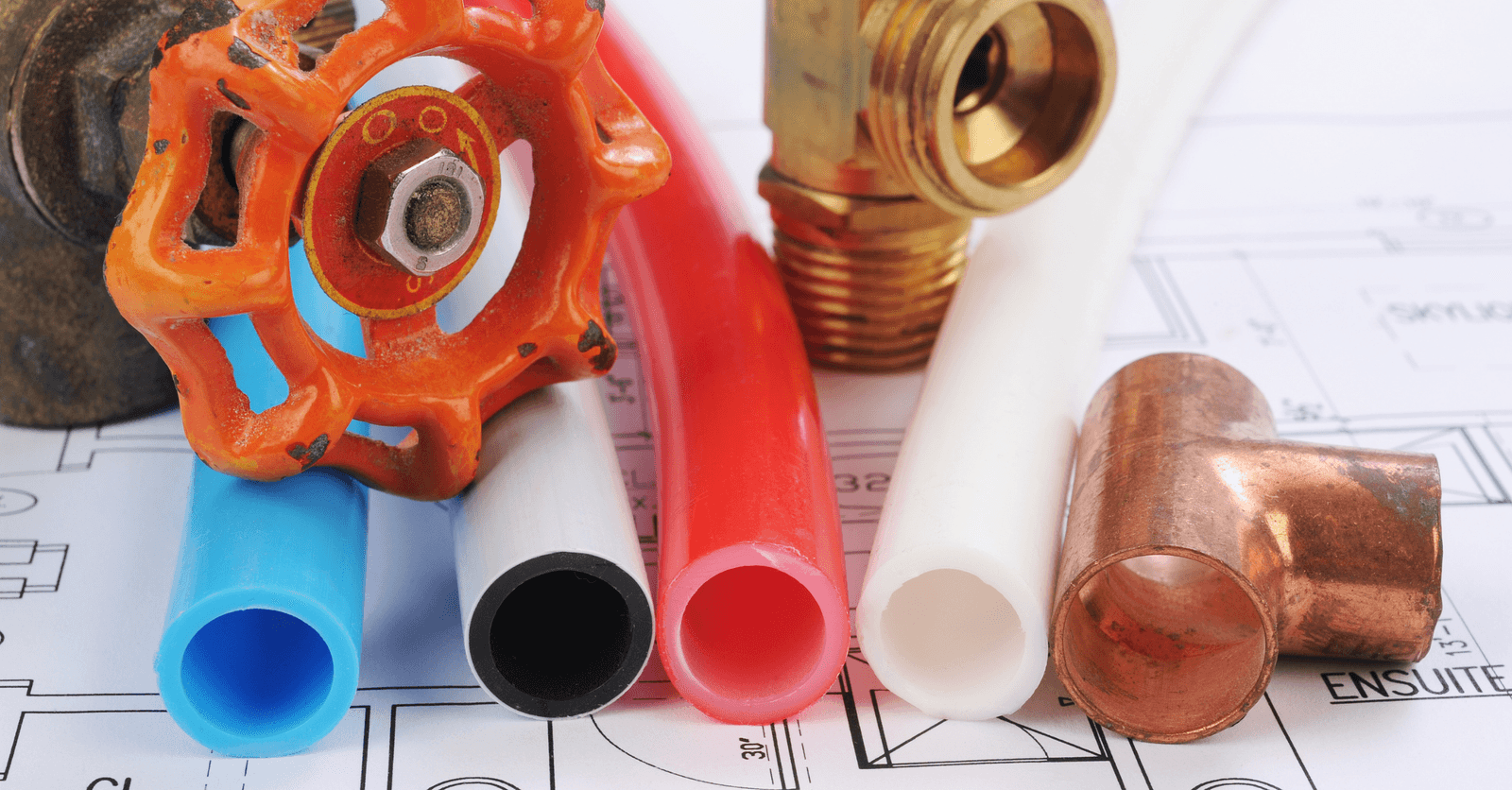

Some general skills that plumbers require include being able to read blueprints, an understanding of various types of piping systems, how the piping is connected, inspecting and determining potential piping or plumbing issues, basic carpentry as well as welding. Schooling and apprenticeship programs can take anywhere between 3 to 5 years, so do be aware that you’re in for the long haul.

Looking for something else?

Related articles

The latest industry news, interviews, technologies, and resources.

Editorial Team

•08 Oct 2025

Several construction trades offer great professional prospects, whether for workers who wish to reorient themselves and change course or for those who wish to improve their skills. Here’s an overview of some of these promising professions!

Editorial Team

•13 Sep 2024

Insulating water supply pipes is a necessary measure that'll help protect pipes from freezing, bursting, or leaking. By insulating your pipes, you’re ensuring the safety and well-functioning of your home or business during the wintertime. It also helps reduce losses and improves the overall system.

Editorial Team

•15 Nov 2024

Have you heard about heat pumps? These innovative and energy-efficient systems are not only environmentally friendly, but they require little maintenance to provide long-lasting heating and cooling to your home.

Editorial Team

•08 Nov 2023

Wallpaper is now making a huge comeback. After paint, it is now the second most popular wall covering product. Find out why so many people choose to cover their walls with wallpaper!

Editorial Team

•21 Jun 2024

Are you carrying out a home renovation or building project? Installing PEX plumbing pipes is a great option. Reputed for its flexibility and durability, PEX pipes are increasingly sought after. It’s a remarkable system given its reliability, resistance, and versatility. What are the upsides? How much does it cost? What are the proper guidelines for installation success? All this and more detailed below.