On-Site Construction Robots to Benefit Workers

By Editorial Team

Updated on August 13, 2025

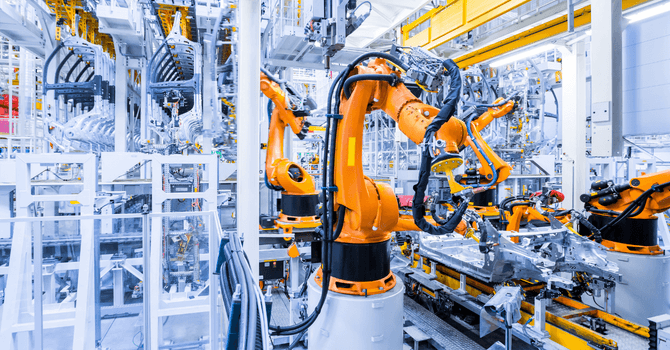

Plenty of industries and various fields are adapting and evolving by introducing new technologies to their production procedures. Even in the construction sector, we’ve been noticing the rise of 2.0 methods, such as virtual or augmented reality, as well as robots working their way around construction sites.

First and foremost, the goal behind embracing such recent innovations is to make up for labour shortages. Naturally, select equipment is also used to ensure the safety of employees by automating certain tasks and, moreover, to improve the overall management and communication between several experts during all stages of a project.

Easily find clients starting today

Get started today and connect with the projects that suit you best!

Construction and Building Site Robot Models

Bricklaying Robots

Source: Canva

SAM100 by Construction Robotics

This robot, which has been on the market for about a decade, can lay about 3,000 bricks a day to build a wall. It can work alone or alongside a mason who can focus on the quality while being less physically challenged.

Hadrian X® by FBR

This robotic arm is fitted to a truck. It can cut and lay 1,000 bricks an hour. Paired with Dynamic Stabilization Technology™ (also known as DST™), FBR robots like Hadrian X® accomplish tasks while maintaining their stability in unstable outdoor environments and when faced with wind, temperature changes, vibrations, and so on.

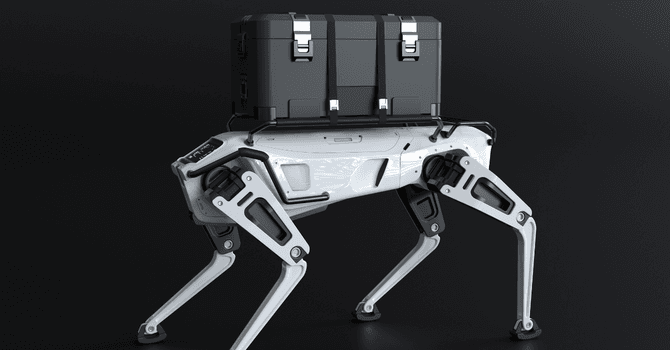

Data-Collecting “Bot-Dog”

Source: Canva

Spot® by Boston Dynamics

This robot accurately captures 360° images and videos. Thanks to a GPS and a pre-set route, it can wander in and out of a construction site and report back a set of valuable data. Such information and functions can be used to draw up documents, measure a location, monitor a less accessible area of the grounds, track worksite progress, automate information, fine-tune software plans, and more. You can even add gadgets to the standard robot, like, for example, water or air quality tests.

Spot® was actually used by the Quebec-based company Pomerleau, on a trial-based period for a project at Place Ville-Marie, in Montréal. Its initial goal was to evaluate the work’s evolution to then compare it against the planned budget and deadlines. As such, Boston Dynamics had the opportunity to help in the more realistic planning stages of large-scale projects.

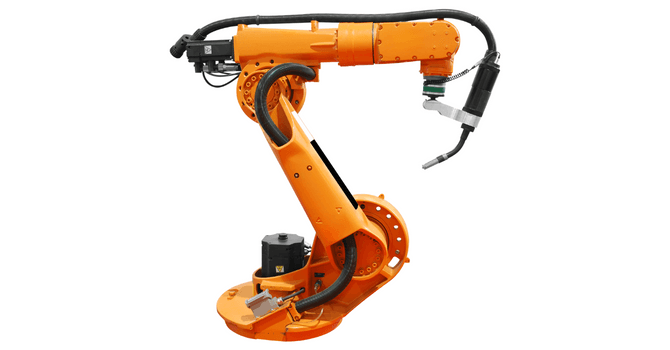

Remote-Controlled Drilling & Demolition Robots

Source: Canva

DXR by Husqvarna

DXR is the company’s demolition equipment range, which has 4 robot models that resemble small-scale excavators. Electric, easy to operate, and especially efficient to demolish just about anything, each model has a unique power, size, and weight so that you can select the one that best meets your needs.

You’ll be able to adapt it according to the worksite by adding hydraulic functions, thermal protection, a telescopic arm, as well as other tools (hammers, crushers, chisels, etc.).

Brokk 110 by Brokk Global

Strong, smart, and versatile, it can climb steps, squeeze in just about anywhere, and fit in an elevator. This demolition robot defines its category as a quality technological innovation.

Jaibot by Hilti

Made for overhead installations, its cordless drilling technology is semi-automated to facilitate strenuous tasks like mechanical and electrical work, plumbing, and interior finishing.

As such, using digital plans, you can program the robot to indicate drilling locations, launch the hole-drilling application (location, diameter, depth, etc.), and remove dust from the site. Jaibot allows you to download data from Autocad or Revit and upload it to your tablet.

Rebar Tying Robots

TyBOT® by Advanced Construction Robotics

This machine is quite imposing due to its size (extendable from 10 to 117 feet). It’s mainly designed to work with large concrete slabs and can function at any given time, to tie 1,110 rebars per hour, even if it’s raining.

In a nutshell, this automated robot self-ties bulk horizontal rebar intersections without pre-programming, pre-mapping, calibration, or BIM input.

Drywall Finishing Robots

Source: Canva

Canvas 1200CX

The 1200CX is a compact machine suitable for both commercial and residential drywall finishing. It measures 34.5″ x 30″, making it 36% smaller than the 1550 system, which helps it fit into tight spaces like small rooms. With all-wheel steering, the 1200CX is easy to maneuver. It operates on a rechargeable battery, offering up to 8 hours of use on a single charge. The machine, operated by a drywaller, uses Canvas’ 2-day finishing system to deliver a high-quality finish quickly, and it can reach up to 12′ in height, allowing for efficient drywall finishing.

Canvas 1550

The 1550 system extends up to 15 feet 5 inches, allowing for high-reaching jobs while keeping operators safely on the ground. It maintains a consistent production rate regardless of height, which helps with scheduling and controlling costs. Suitable for larger spaces and high elevations, it uses Canvas' 2-day finishing process to achieve level 4 or level 5 finishes. The 1550 is ideal for projects such as data centers, industrial sites, and educational buildings.

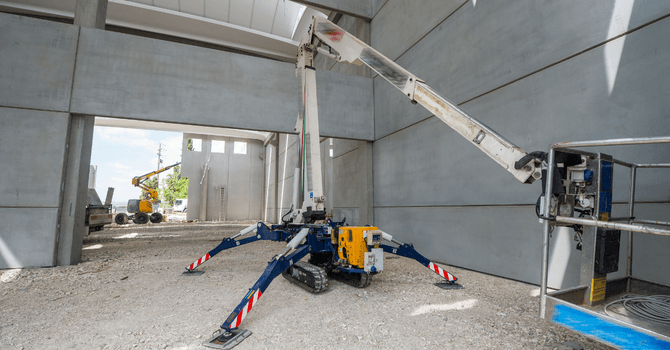

Embracing Robots in Your Renovation or Construction Company

Source: Canva

Robotics won’t entirely take over the potential of abled-bodied workers. However, such machinery can handle certain tasks to allow professionals to focus on work that requires more attention or that’s more time-sensitive or unplanned, even.

Using robots is a time-saver and prevents workers from performing repetitive or risky movements that could lead to injuries or accidents. As such, they’re pretty useful to keep labour forces safe and reduce CNESST premiums. Such machinery can also be of great help when it comes to lifting heavy loads, having an overhead view, or maneuvering efficiently in confined spaces.

Prior to purchasing all the gadgets available, from the tiny drones to the giant ones that install drywall, make sure that it actually meets your long-term needs:

Since robots are designed to carry out very few and precise tasks, they could be useful on one work site, but useless for another one of your contracts.

Costs can be up in the hundreds of thousands of dollars, so it’s best to weigh the robot’s real impact on your productivity, especially if you have a small company with a limited budget.

Get your employees’ feedback on the matter first, it could save you tons. If they think the tool won’t be necessary or could somehow hinder their efficiency, your investment risks being dead money. Sample demos or participate in some sort of group workshop to make an informed assessment before officially committing to a purchase.

Don’t rely solely on a salesperson’s opinion to make a decision. Consult several reliable sources like the BIM Québec or Batimatech websites. Also, discuss it with other contractors that might have worked with select robots.

A Growing List of Valuable Construction Robots

Needless to say, there's no need to go through the whole list of available robots on the market to make your life easier. The list would be never-ending if we’d added mapping and finishing robots, 3D printing robots, surveying drones, etc.

Instead, let's wrap it up by saying that the down payment on a robotic worksite helper is, of course, considerable and requires some forethought. However, you’ll save on labour costs and have a backup plan in place as Baby boomers near retirement by 2030, with few to replace them.

It's a hot topic right now; it's interesting, constantly evolving, and well worth keeping informed about!

Looking for something else?

Related articles

The latest industry news, interviews, technologies, and resources.

Editorial Team

•18 Mar 2025

In Ontario’s bustling construction industry, the need for skilled labour and efficient staffing solutions has never been greater. Construction staffing agencies play a crucial role in bridging the gap between construction companies and the talented workforce they require. At RenoQuotes, we are committed to helping you understand the benefits and processes of working with these agencies to ensure your projects are staffed with top talent and executed seamlessly. Let’s explore the essential role of construction staffing agencies and how they can help you achieve your project goals.

Editorial Team

•29 Nov 2024

At the Centre de formation professionnelle des Portages-de-l’Outaouais, students are flanked with signs promoting a “variety of trades grouped under the same labourers' union in Ontario.” Welding job opportunities are advertised with wages such as $54.62 an hour, and heavy machinery operators $61.02 per hour.

Editorial Team

•08 Nov 2023

Although not all households are able to accommodate a central-air system, during the summertime even they will need a way to stay cool. Luckily the saviour comes in the form of a wall-mounted air conditioner.

Editorial Team

•23 Jul 2025

Not a few weeks ago, winter seemed like a distant memory, but not anymore. As the coldest month sets in, it’s crucial to be prepared. When it comes to the inside of your home, preparing for the cold front includes proper insulation, sealing all exterior leading doors and windows, applying weather-stripping, and so on.

Editorial Team

•08 Nov 2023

The bedroom is the definite haven of the home. Depending on your living arrangements, this room may be the only space offering you a little bit of peace, quiet and privacy. Of course, you’ll need it to be as organized as possible if you’re spending endless hours tucked away in your bed.