How to Mitigate the Effects of Plastic Use in the Construction Industry

By Editorial Team

Updated on October 9, 2024

Plastic is a hugely exploited building material since it’s durable, waterproof, supple, and lightweight. However, just like its many other daily uses, it definitely has a bad reputation. Subsequently, several companies are looking to take major steps to reduce its harmful effect on the environment.

Though still far from the ideal outcome, governments and scientists are studying methods to improve the conception of plastic materials. As such, they’re establishing certain rules to help reduce biodiversity damage, curb plastics polluting the oceans, minimize waste when recycling, and so on. Single-use plastics are predominantly targeted by such initiatives giving value to renewable and reusable materials.

As a construction contractor, on what level can you tackle this problem to make your worksites more eco-friendly?

Plastic Use in the Construction Industry

Source: Canva

Without delving too deep into the scientific details of it all, plastic is a high-molecular compound that’s derived from petroleum, natural gasses, or plants. It can be grouped into two main categories: single-use or reusable.

In Canada, the construction industry is a major consumer of all types of plastics since it’s a versatile and affordable product. It’s lightweight and malleable, making its transportation and installation easy. Waterproof, corrosion- and rot-resistant, these definitely slow down its deterioration process. Also, its numerous qualities as well as the substantial savings made are presented as non-negotiables for contractors.

However, waste derived from its various uses is, unfortunately, generated throughout its entire process: from manufacturing to demolition, by way of transportation and construction itself. Moreover, some materials are rather difficult to recycle, such as PVC and flame retardant products.

Nonetheless, note that it’s mandatory, for safety measures in some cases, that some materials aren’t decomposable or too “green.” Their use isn’t hazardous to the environment, it’s the complete opposite. For example, who would want the polystyrene blocks fitted to the new Champlain Bridge to be biodegradable? On a more serious note, the product’s durability allows for a near-permanent installation, such as pipes, which reduces waste pollution.

The Most-Used Plastics in the Renovation and Construction Industry

Source: Canva

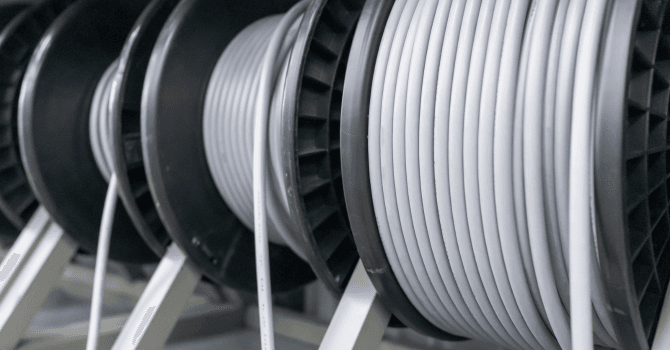

The types of plastics most used in construction are as follows:

Polyvinyl chloride (PVC)

High-density polyethylene (HDPE)

Expanded polystyrene (EPS)

There's no way to accurately list the many uses of this popular material in terms of building and renovation work, but here are a few: wiring, piping, joints, doors and windows, insulation, paints, tanks, mouldings and formwork, road signs, filtration, flooring and exterior cladding, etc. Nowadays, wood, glass, and metal are even being swapped for plastic.

Ways to Limit Plastic Use on Worksites

Source: Canva

The biggest challenges remain sorting, reusing, and recycling end-of-life plastics. That's why it's important to embrace good, sustainable, and eco-friendly practices from the get-go. Not only is the planet's health at stake but also your company's reputation.

If you're looking to move conscientiously away from the overuse of plastic products, you'll first need to formulate an action plan. For this, you'll need to evaluate the set of measures that are most effective and realistic for you.

Focusing solely on biodegradable, bioplastic, and composite products, though it might seem like the most logical and obvious solution, isn't your only option. You have to think globally, on a multi-level, eco-friendly approach, not only in terms of material components and use. Recycling construction waste and developing a circular economy is more profitable long term.

A well-thought-out strategy takes into account both advantages and disadvantages of using plastic for such and such. Hence, consider the possibility of swapping it out by weighing its effects, from start to finish (raw material extraction, manufacturing, transportation, function, safety, recycling, disposal, etc.).

As such, it’s best to start by implementing simple and easy-to-control actions. You can educate and/or raise awareness among your employees by urging them to bring reusable drinkware and tumblers, properly dispose of their waste, even if they're in a rush, and so on. You can also take it one step further by giving out reusable bottles with the company’s logo on them and having a water refilling station. Lead by example: purchase cleaning products in bulk and ban the use of single-use plastic like straws and utensils during meetings and gatherings.

Follow the 3Rs and beyond:

Reduce

Reuse

Recycle (or compost)

Value energy recovery

Responsible waste disposal

Goals Targeted by Limited Plastic Use

Source: Canva

The expected results consist of improving waste collection, reusing, and recycling plastic waste issued from building industry ventures.

You can save by using less expensive, recycled building materials to keep them out of landfills. The entire life cycle of plastics demands change. Solutions must be thought out in terms of economic needs and capacities and should include the province's unique climate conditions.

Check out the following for more concrete details.

Examples of recycled materials used on building sites

1) Polystyvert, Pyrowave, Polyform, and Groupe Gagnon: Quebec-based companies striving to give a new meaning to polystyrene, a material widely used in the construction industry.

2) A German developer and builder saved 1,613 tons of concrete and 136 tons of CO2 emissions by using recycled plastic to build a residential high-rise. In due part to a patented void-former system, the steel-reinforced air bubbles replaced 35% of the reinforced concrete that would normally have been used for the slabs.

3) A company in the United Kingdom collaborated with clients and suppliers to reduce single-use plastics. One of the collaborators was able to save, what would add up to 40 tons of plastic waste a year among other things, by limiting the use of hazardous packaging. Employees were also provided reusable shoe covers and a closed-loop system for protective plastic sheeting.

4) During a commercial construction project in London, contractor Multiplex swapped out plastic mastic tubes for foil mastic tubes. This initiative led to saving 9,290 single-use tubes as well as reducing the volume of waste that would normally be generated from such a project by 96%.

How can I dispose of construction and demolition waste?

Whether you outsource waste management to a recycling company or do it yourself, there are plenty of options available to minimize your ecological footprint.

Here are a few topics to be discussed as far as “green managing” your waste and construction worksite:

Sustainable designs;

Bio-based materials;

Ecological designs;

Converting existing buildings;

Advanced framing;

Redirecting construction, renovation, and demolition waste to appropriate resources and ecocentres.

To learn more about sustainable development and demolition waste, you can:

Join CPEG (Quebec Business Council on the Environment), which supplies a lot of information, has several committees, and more.

Check out the RECYC-QUÉBEC website, which details what one should do with all types of waste and offers relevant information for companies.

Consult the Ecohome website to know how to divert waste and reduce GHGs.

Look over carbon material databases and inventories to review the carbon levels present in various forms of plastics.

Get new contracts for your construction or renovation company

RenoQuotes.com can help you get new contracts. We get new project proposals from clients seeking top-rated and trustworthy renovation professionals like yourself. To get started, simply fill in the form on our homepage (it only takes a few minutes) and receive information regarding potential clients by way of our services.

Dial 1-844 828-1588 to speak with one of our customer service representatives.

Looking for something else?

Related articles

The latest industry news, interviews, technologies, and resources.

Editorial Team

•21 Aug 2025

Glued-laminated timber framing is tomorrow’s building material. Not only does it have numerous advantages, but it also reflects the environmental shift underway across the construction industry.

Amanda Harvey

•08 Nov 2023

For an entrepreneur, receiving a large number of requests for various projects bodes well for business. However, your phone ringing off the hook shouldn't be enough to reassure you.

Editorial Team

•14 Jan 2025

The sheer size of a home's plumbing system can make plumbing issues seem rather complex. There are pipes in the basement, drains outside, bits of pipe coming out on the roof, valves, and J-bends under the sinks...

Amanda Harvey

•14 Mar 2024

Although renovations are often motivated by a search for greater comfort and some aesthetic improvement, some may be planning renovations to sell their home. If this is the case, renovations that work to increase the market value of your home are the ones to consider.

Editorial Team

•17 Feb 2025

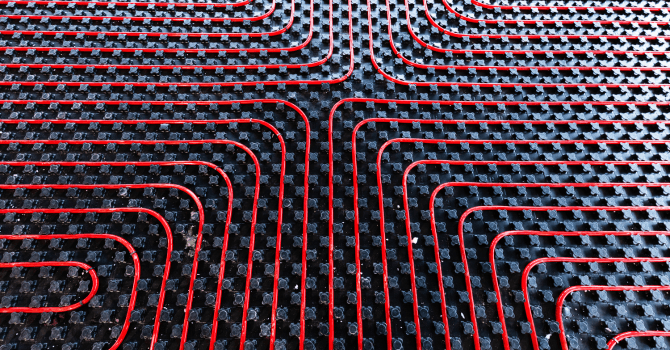

Electric underfloor heating systems, also known as radiant underfloor heating, are a modern and efficient solution, appealing to an ever-increasing number of homeowners. Why? Because these systems allow heat to spread evenly from the ground up, eliminating drafts and providing unparalleled thermal comfort.