Aluminum welding is considered one of the most dangerous metalworking trades. This line of work mandates expert technique and constant safety measure awareness. The hazards inherent to the trade can have disastrous effects on the health and safety of workers. Consequently, this article will focus on the various dangers faced by aluminum welders and outline essential safety measures to minimize these risks.

The Dangers of Aluminum Welding

Source : Canva

Dangerous Radiation

One of the foremost dangers aluminum welders are exposed to is the radiation produced by the electric arc during the welding process. This radiation—a combination of ultraviolet (UV) and infrared (IR) rays—can cause severe eye injuries and acute skin burns. UV rays can cause corneal injuries, also known as “arc eye,” whereas IR can lead to extensive skin burns.

Toxic Fumes and Gases

Aluminum welding produces toxic fumes and gases, such as ozone, nitrogen oxides, and metal particles. Inhaling such substances can cause severe respiratory issues, including bronchitis, chemical pneumonitis and, in the long run, chronic lung diseases. Welding fumes may also contain heavy metals, such as lead or cadmium, which are quite detrimental to one’s health.

Explosion and Fire Hazards

Source : Canva

Aluminum welding involves the use of extremely high temperatures, which can significantly increase the risks of fires or explosions. Sparks and molten metal splatter can easily ignite combustible materials found near the welding site. Moreover, welding certain metal alloys can release hydrogen, a highly flammable and explosive gas.

Electrical Hazards

Aluminum welders work with powerful electric equipment, such as welding machines, transformers, and electrical cables. Poor maintenance or inappropriate use of said equipment can lead to severe—potentially fatal—electrical shock. The risk of electrocution is particularly high in humid settings or when the equipment used is defective.

Physical Hazards

Aluminum welding often involves working in uncomfortable positions, repetitive movements, and lifting heavy loads. These factors can lead to musculoskeletal disorders (MSD), such as joint and back pain and tendinitis. Furthermore, the intense noise generated by the welding machines can lead to permanent hearing damage if the appropriate protections aren’t employed.

How to Stay Safe When Welding: Safety Management & Hazard Prevention Measures

Source : Canva

Given the sheer amount of trade-related risks and hazards, putting together strict prevention and protection measures is essential to ensure the safety of workers.

Training and Awareness

Proper training and continuous awareness regarding the risks of aluminum welding are paramount. Welders must be made aware of the specific risks associated with their line of work as well as the proper safety measures to follow. They can also be trained in the proper use of personal protective equipment (PPE) and how to handle materials safely.

Personal Protective Equipment

Wearing the right personal protective equipment (PPE) is indispensable for all aluminum welders. PPE includes trade-adapted respirators to filter toxic fumes and gases, welding goggles to shield the eyes from dangerous radiation, insulated gloves to prevent burns, as well as spark- and molten metal splatter-resistant protective clothing.

Proper Ventilation

Effective ventilation is crucial to evacuate toxic fumes and gases produced while welding aluminum. Ventilation systems must be designed and installed in such a way as to trap and exhaust contaminants at their point of origin. Regular air quality checks must be carried out to ensure the level of contaminants remains within an acceptable threshold.

Fire and Explosion Hazard Management

Source : Canva

Strict measures must be established to prevent fire and explosion hazards associated with aluminum welding. This involves removing combustible materials from nearby workstations, having proper fire extinction systems in place, and training welders in emergency procedures in the event of a fire or explosion.

Equipment Maintenance and Inspection

Regularly maintaining and inspecting welding equipment is essential to guarantee the gear’s proper functioning and safety. Electrical cables, welding machines, and other equipment used must be inspected and replaced if necessary to mitigate the risks of eclectic shock or other workplace accidents.

Ergonomic Set-Ups and MSD Prevention

It’s important to establish suitable ergonomic measures to prevent musculoskeletal disorders. This includes the use of welding equipment designed to reduce physical exertion, implementing task rotation to prevent repetitive movements over extended periods, and scheduling regular breaks to allow workers to rest and unwind.

How to Protect Aluminum Welders

Aluminum welding is undeniably a dangerous trade, but its risks can be significantly reduced with proper training, suitable personal protective equipment, and stringent safety prevention and control measures. Both employers and workers need to take these risks seriously and collaborate to create a safe and healthy work environment. By adopting a proactive approach to workplace safety, aluminum welders can perform their tasks confidently, minimizing risks to their health and well-being.

Looking for a job in the renovation or construction industry

RenoQuotes.com can guide you in your job search in the renovation industry. Tell us about your career prospects, and we'll help you get in touch with contractors who are likely to be interested in your skills, free of charge. Simply fill in our form (it'll only take a few minutes) and we'll take care of sending your candidate application to employers.

Dial 1-844 828-1588 to speak with one of our customer service representatives.

Looking for something else?

Related articles

The latest industry news, interviews, technologies, and resources.

Cynthia Pigeon

•03 Nov 2025

Are you thinking about replacing your exterior siding? Without a doubt, such a project will revamp your house’s exterior, especially if it’s not a newly built residence.

Amanda Harvey

•22 Apr 2024

Classic style doesn’t have to mean being outdated or entering into a traditional time warp. Although this style is rooted in tradition, classic home decor incorporates fine architectural details with sophistication. It enlivens the timeless elements of the past while remaining contemporary and in touch with current trends.

Editorial Team

•11 Mar 2024

As a contractor, understanding the impact a renovation project is likely to cause on the environment is second nature. In the midst of it all though, it can sometimes be hard to keep eco-friendly practices at the forefront, even at a time when such thinking is at an all-time high.

Editorial Team

•08 Nov 2023

Over the last few years, the issue surrounding homes built on contaminated land has been making headlines. Not only does this bring forth a lot of questions regarding the municipal administration in office at the time, but it also elicits a reflection on the repercussions of the situation in regard to citizens as well as the necessary measures needed to fix the problem.

Editorial Team

•08 Nov 2023

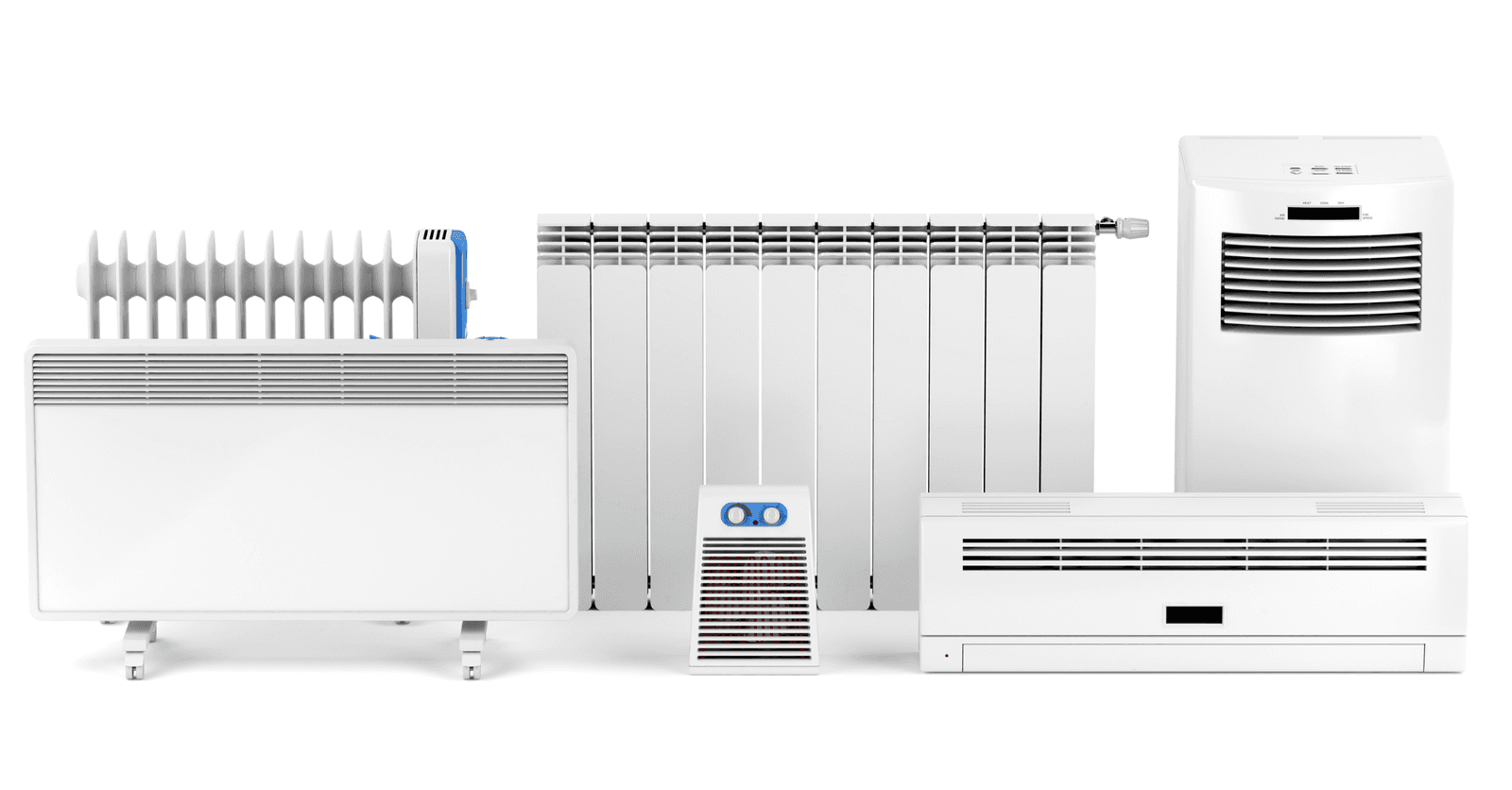

During your home-building process, making an informed decision regarding the type of heating system you’d like installed is of utmost importance. Gas, hot water, or electric heating solutions, no matter the system, each have their advantages and disadvantages. However, electric heaters are the most commonly used heating solution in the province of Quebec, and most residents aren’t holding back from renovating their entire heating system to install residential electric heaters.