A Durable and Weatherproof Solution: Composite Flooring

By Editorial Team

Updated on November 8, 2023

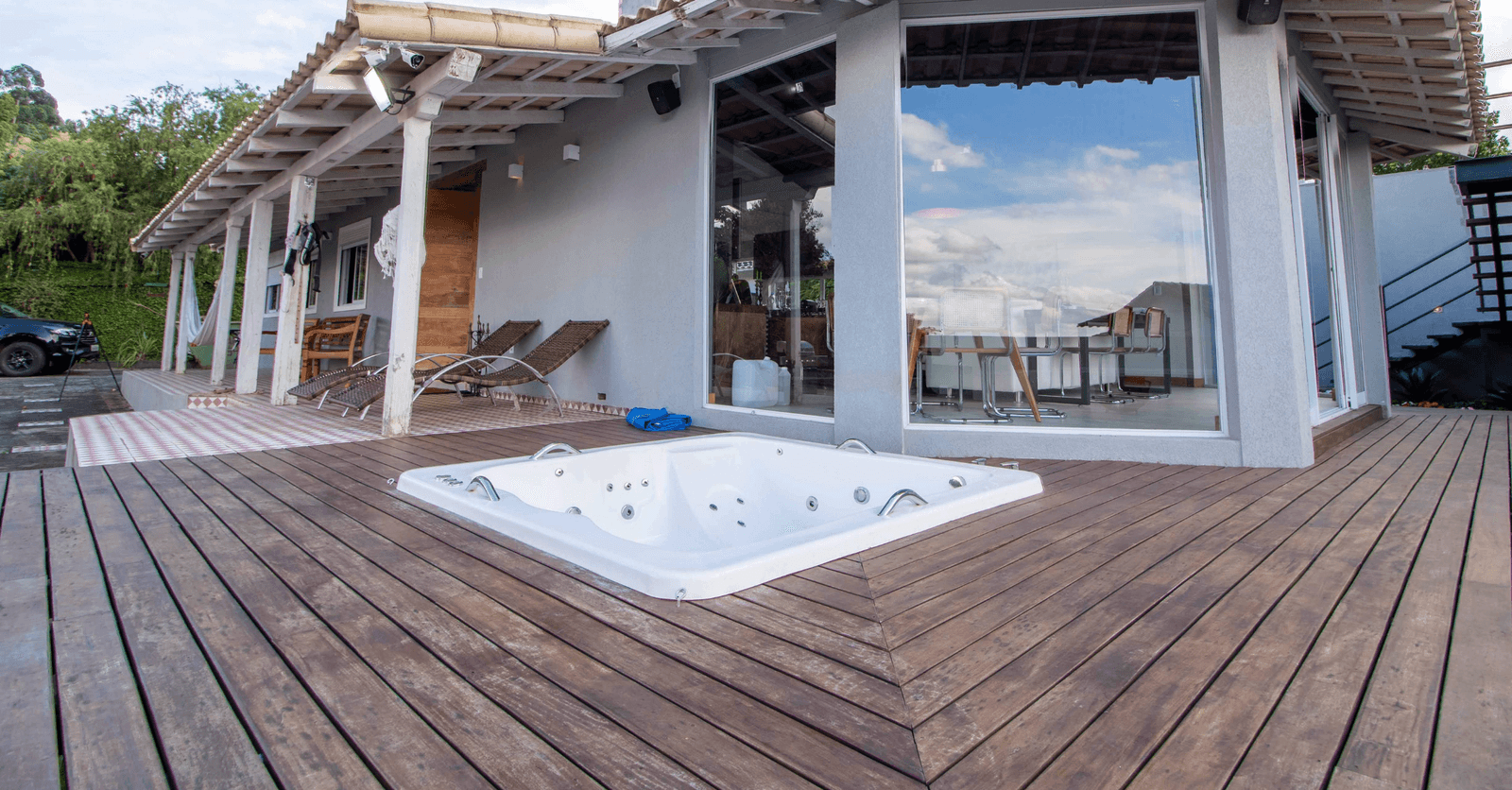

Who doesn’t like wooden floors? The wide-ranging species are sought-after, whether installed inside or outside. However, while wood may be well-acclimated and low maintenance inside your home, it’s another tale when facing Mother Nature in your backyard.

Wood decking, albeit a timeless favourite, does require a hefty amount of care. Be it ipe, cedar, or pressure-treated lumber, there’s no way around it. Since we’re usually short on time to paint, stain, and seal it, and it can be tough to come by a professional to do the work for us, sooner or later, we find ourselves with poorly maintained flooring that’s wearing out and deteriorating prematurely.

Hence the reason why composite decking is an ever-growing favourite. It’s durable, eco-friendly, and high performing, which means you can benefit from wood’s beauty, lustre, and shades, as well as the richness of its fibre, stress-free, and, without cutting down a single tree.

How to Choose Composite Decking

Source: Canva

There are different types of composite flooring grouped according to the following 4 factors:

Profile: hollow or solid boards

Plastic design: high-density polyethylene (HDPE), polypropylene (PP), PVC, or expanded PVC

Filler base: wood flour, paper, rice hulls, bamboo, hemp, peanut shells, etc.

Extrusion type: first generation or co-extrusion

Wood-Plastic Composite Profile

Hollow boards were first launched on the market at the beginning of the 1990s, and because they’re made with 40% less material than solid boards, they’re much cheaper. We like the fact that they’re lightweight, facilitate construction, speed up the process, and can be installed on an existing structure that wasn’t built for WPC (wood-plastic composite) boards.

A quality product will easily withstand extreme temperature variations. On the other hand, hollow composite boards are rather water- and humidity-vulnerable (boards dilate and crack due to stagnant water and freeze), are more brittle and damage-prone under physical impact, and can’t be worked like real wood (cut or screwed) since their profile is partly hollow.

The arrival of solid boards on the market solved these different issues. While they’re heavier than so-called engineered (hollow) boards, they more closely resemble wood planks. Solid WPC boards are better for soundproofing noise and footsteps (or swift steps) than hollow boards. Lastly, they don’t necessitate a skirting board or end caps for a put-together, finished look.

Solid boards still have their share of drawbacks, such as their weight, and tendency for expanding, contracting, or warping when exposed to harsh weather conditions. They also require a bit more effort during the building process.

Wood-Plastic Composite Board Design

Other than being hollow or solid, the various other products used to design composite flooring or decking are divided into two categories based on their plastic composition: polyolefins (polyethylene and polypropylene) and PVC.

Polyolefin-based boards are more supple and must be installed on a structure with a tighter mesh because of just how flexible they are. They’re more easily worked and perfectly mimic the look of wood. Heat, directly on polyethylene, has the added bonus of eliminating micro scratches caused by our four-legged best friends or by pushed-aside furniture. Lastly, polypropylene is harder and more difficult to extrude, both of which render the product’s quality inconsistent.

PVC is more rigid, oftentimes more expensive, as well as more prone to cold-weather breakage. Paired with wood fibre, a denser product than traditional composite can be designed. While PVC boards are practically all hollow, solid decking boards can be produced with expanded PVC.

Composite Wood Filler Base

By “filler base,” we mean the percentage of wood paired with plastic matter, which varies from one product to another.

Composite wood is typically made with recycled wood particles (most notably waste softwood or hardwood in Europe and America) and polymer resins. The filler material allows the board to expand, while the wood fibre serves as a stabilizer; the goal being finding the perfect balance.

As such, the wood content may vary between 15% to 70% in a filler base mix. A significant amount of wood (or wood flour) doesn’t necessarily mean higher quality as the latter speeds up the composite’s discoloration process and heightens its vulnerability to moisture. Therefore, the percentage of wood fibre used during the manufacturing process shouldn’t exceed 60%.

NOTE: Polypropylene can encase a higher percentage of wood fibres than polyethylene.

Deck, Terrace, or Balcony: How to Install Composite Decking Outside

Source: Canva

Prior to jumpstarting your composite decking project, consult your municipality's urban services to familiarize yourself with the current regulations. In most cases, you’ll need to submit a sketch of your project and request a permit.

Composite Deck Structure Requirements

Building a composite wood deck is done according to a set of distinct requirements. As such, from the get-go, the foundation on which the boards will be placed must meet specific criteria.

joists and stair stringers must be fitted every 12-inch;

the joists have to be doubled where the boards are joined together at their ends;

H-shaped joists must be used where the boards will be met with a perpendicular directional change;

the joists must be coated and weatherproofed with a bitumen membrane;

the deck must have proper airflow (there has to be a 12-inch clearance between the deck’s surface and the ground) since excess humidity will warp the boards. As such, it’s recommended to install a lattice skirting that will seal the gap while promoting adequate airflow.

Installing Composite Boards

Composite products available for outdoor decking are as follows: stair nosing, boards or tiles, and skirting. Here are some recommendations to consider whilst assembling:

avoid, as much as possible, cutting or trimming the composite boards. When necessary, use a tungsten carbide-tipped blade;

a wood sealant must be applied with a paintbrush on the cut ends;

install the boards at a 90-degree angle to the joists;

because composite wood is prone to expansion and contraction, avoid connecting one board end to another. If it must be done, double up on the joists positioned at the junction. That way, each board can be securely fastened to its own joist;

when installing the boards, start with the stair nosing and work your way toward the house.

Fastening Hardware

Never screw or nail composite boards directly to a structure. Only use the hardware supplied by the manufacturer during installation otherwise the warranty will be null and void.

Typically, there are three different types of fasteners used:

1. Basic clips, used to securely attach the boards to the joists;

2. Starter clips, used to fasten the initial deck boards;

3. Locking clips, designed to connect and lock two boards, end to end, preventing unwanted side-to-side movement.

TRICK OF THE TRADE: Should you prefer square tiles, there are 12-inch by 12-inch (30 cm by 30 cm) composite tiles sold on the market. This type of durable flooring is easy to install and will revamp your worn outdoor space in no time.

What are the pros and cons of composite wood?

Source: Canva

If you’ve opted for composite decking boards, yet aren’t sure which to choose amongst the near dozen available on the market?

Since comparing and contrasting the pros and cons can be rather complex, here are a few key factors on which to base your decision.

Composite Material’s Moisture Resistance Level

Composite decking’s performance when exposed to humidity significantly varies from one brand to another. Moisture resistance is directly linked to the quality of the process by which the wood fibres are enclosed in plastic.

Therefore, abide by the guidelines when it comes to recommended clearance between the decking and ground, as well as the required airflow beneath the structure.

Note that MoistureShield composite decking is the only brand that guarantees a ground-level, underground, and underwater installation.

Available Warranty

Warranties significantly vary from one brand to another. Some warranties cover manufacturing defects, discoloration, moisture intrusion, rotting, stains, warping, cracking, and insect-related damage… Look over what’s covered and for what period of time!

Typically, the warranty period is between 25 to 50 years, depending on the chosen brand and model.

Have composite materials ever been the subject of structural field failures?

Some brands have been the subject of class action lawsuits due to manufacturing defects. Choose quality products retailed by a reputable and reliable company.

Amount of Heat Absorbed by the Product

Composite decking boards tend to absorb heat and become quite hot during peak summer season. If you can’t tread barefoot on your deck, terrace, or balcony for the better part of the summer, you won’t be able to benefit from it as intended.

Weigh how the product reacts under various weather conditions prior to making up your mind. Some products absorb up to 35% less heat than others, thereby limiting contact heat transfer.

Percentage of Recycled Materials Involved in its Making

As for the percentage of recycled materials used, it also varies from one product to the next. Considering that some composite wood is made with 95% recycled materials (milk cartons, grocery bags, pallet packaging), makes for an appropriate choice that allows you to significantly reduce your environmental footprint.

Protective Coating

Some composite materials issued from first-generation designs are more prone to discoloration and staining over time and necessitate periodical cleanings. They’re also more prone to scratching. Others benefit from a protective coating that guarantees the product’s durability.

Product Designed for Our Weather

Products designed and manufactured in North America are quality composites and PVC, suited to our weather conditions. While these are more expensive than products imported from Asia, they perform better when exposed to notable temperature variations.

Overall, if you don’t want to go wrong, you can definitely rely on reputable brands that have been proven effective in Quebec.

Composite Boards: Cost and Colours

Source: Canva

Low-priced products available in big-box stores often have a poor-quality shell that absorbs heat a lot more. These products also often have porosity-related issues that result in discoloration, they require more maintenance and are subject to expansion.

The products designed and manufactured in North America are made according to our weather conditions. They’re often more expensive, but the quality of their manufacturing and warranty is often well worth the investment.

One can always save money by opting for hollow boards rather than solid ones. You’ll be saving on your purchase, but also on building time. However, choose a quality product and make sure the design (faux wood finish) meets your aesthetic criteria.

A few price points:

$76 to $126 for a 16-foot long, 5.5-inch wide board

$9.39 per linear foot for a 12-foot long, 8-inch wide board

$49.99 for a 12-inch by 12-inch tile

As for shades, composite wood is spoiled for colours. Shades range from all the most aesthetically pleasing hues, whether you prefer a natural-looking board (Maple, Acacia), to warmer tones (Cocoa, Dark Coffee, Sandy Beach), driftwood (Seashell, Slate Grey, Barnwood), or a pretty faux torrified wood (Carbonized, Rustik).

PRO TIP: Light colours won’t absorb as much heat as dark shades. As such, one may notice a 5- to 13-degree Celcius difference between two same-brand composite decking boards, one light-coloured and the other dark-coloured.

Composite Flooring: Weatherproof and Durable

Composite decking is highlighted as an exceptional flooring option, offering both unparalleled weatherproofing and unmatched durability. Such modern materials blend both wood’s aesthetic and plastic’s robustness, thereby creating decking that withstands:

UV rays

humidity

mould

insects

Although the initial cost is slightly higher than that compared to traditional alternatives, you’ll be benefiting from a long-term solution that requires little maintenance. Composite flooring encompasses the perfect equilibrium between shape and function, for appealing outdoor spaces that can withstand harsh weather. As such, it makes for a wise choice for those who aren’t looking to compromise in terms of durability or aesthetic appeal.

Get 3 quotes for your composite flooring project

RenoQuotes.com can help you get quotes for your flooring project. By submitting your project, we’ll put you in contact with top-rated contractors. Fill in the form on the homepage (it only takes a few minutes) and get estimates from trusted professionals.

Dial 1-844 828-1588 to speak with one of our customer service representatives.

Looking for something else?

Related articles

The latest industry news, interviews, technologies, and resources.

Editorial Team

•08 Nov 2023

Feeling like your bathroom needs a makeover? Need to increase your storage space? Renovation projects can be very expensive. Plumbing, flooring installation and custom-made furniture are all projects that can easily become quite onerous.

Editorial Team

•04 Oct 2024

Technically speaking, DIYing your entryway decor with tile is entirely possible. However, from an aesthetic point of view, the whole process can be quite risky.

Editorial Team

•20 Sep 2024

Pool coping—the caps lining and securing your pool shell's edges—is a key swimming pool design feature. Its installation, which bridges the gap between aesthetics and safety, requires special attention, particularly in material selection and installation steps. So, how can you be sure you’re making the right choice and how is coping installed? Follow along with our guide.

Editorial Team

•08 Nov 2023

Renovating a kitchen can be expensive, and depending on the changes made, your budget can quickly increase. Of course, you don’t have to tear down your cabinets or demolish a wall in order to tastefully renovate and offer your kitchen a new look.

Editorial Team

•09 Feb 2026

As a budding young contractor, you know better than most that the building industry is constantly evolving—and that success isn’t just about mastering tools and techniques. It’s also about preparing strategically for the upcoming renovation season. New materials, updated codes, emerging technologies, and changing regulations mean that professional know-how is never static; it grows through continuous learning, practical experience, and smart business planning.