Cellular Concrete: An Innovative, Durable, and Multi-Use Material

By Editorial Team

Updated on August 19, 2025

It was in 1923 that cellular concrete, developed by Swedish architect and researcher J.A. Eriksson, first appeared. Albeit it isn’t ground-breaking technology, it’s still considered innovative as it has contributed to building extremely energy-efficient, modern-day single-detached homes.

Come along as we delve further into detail regarding this material, with concrete-like qualities, that’s striving to find common ground on Quebec-based worksites.

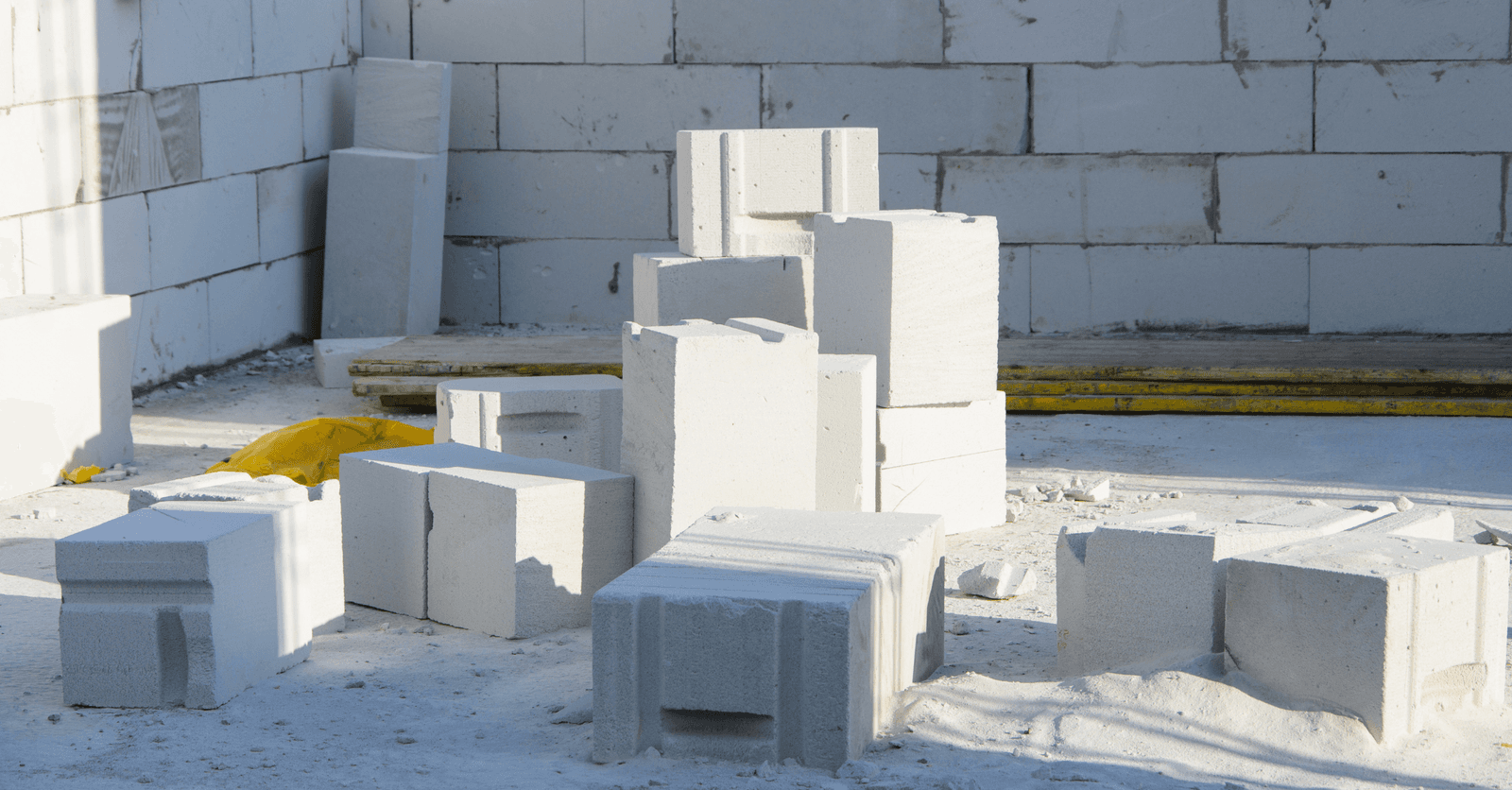

What is cellular concrete?

Source: Canva

Cellular concrete, which is also branded as aerated concrete, lightweight concrete, or foam concrete, is a type of concrete that isn’t formulated with aggregates but to which millions of air voids are added. Once hardened, the mixture takes on the shape of closed microcells to prevent capillary rises.

Cellular concrete boasts numerous advantages, giving rise to its appeal, not only in terms of residential construction but also in jumpstarting large-scale projects. It’s suitable for both interior and exterior use to build walls, partitions, ceilings, low retaining walls, lintels, beams, etc.

Easily find clients starting today

Get started today and connect with the projects that suit you best!

How is cellular concrete formulated?

Cellular concrete is a meticulously formulated material that includes closed concrete microcells, set apart by thin walls preventing capillary rises.

While the amount of each ingredient may vary, the composition remains the same. Sand (44-65%), lime (10-15%), and cement (3-20%) are mixed with water (between 15% and 20%) to make a paste that will expand as a result of the added aluminum paste or powder (0.6%). However, aluminum is used in specific cases. The voids created as a result of trapped air—hence the term cellular—significantly heighten the volume.

After moulding and heating the paste at 180°C, it solidifies into blocks. These blocks consist of 80% concrete or solid matter, with the remaining 20% trapped water.

Soundproofing Properties

Cellular concrete is valued for the soundproofing properties in its making. Therefore, it can be used as an insulating base layer beneath a structural slab, relacing expanded polystyrene panels.

Phonic insulation increases based on the mass. While using thinner cellular concrete blocks isn’t optimal, soundproofing insulation can be easily incorporated.

How thick is cellular concrete?

Cellular concrete comes in block, tile, or panel form, with widths ranging from 5 to 30 mm.

However, what’s more surprising is its weight. The density of cellular concrete oscillates between 1,100 and 2,000 kg/m3 (that of standard concrete is roughly 2,300 kg/m3). For comparison’s sake, it’s four times lighter than water. If you were to throw a cellular concrete block into water…it would float!

Manufacturing Process of Cellular Concrete

Making cellular concrete is done according to the following four steps:

Prepping, dosing, and mixing the previously mentioned materials.

Preparing the moulds, then pouring the paste, letting it expand and harden.

Cutting it with a steel wire

Curing it, so inserting the material in an autoclave for 10 to 12 hours, at a temperature of 180 degrees Celcius.

What are the pros and cons of cellular concrete?

Cellular concrete has amazing characteristics, making it an exceptional material.

PROS

Source: Canva

Excellent thermal insulator

Cellular concrete, with its million little stable air voids, has impressive insulating capabilities. With it, indoor temperatures can be controlled for higher comfort levels and definite air conditioning and heating savings are achieved. From a global warming perspective, it will be especially efficient during summertime, mitigating sudden spikes in temperature.

A wall made with 20 cm-thick cellular concrete blocks, with a 10 cm insulator, has a higher thermal performance than an equally thick, standard-issued masonry wall. While compelling, even this thermal efficiency isn’t enough when confronted with the very cold temperatures that Nordic countries experience.

Lightweight

Cellular concrete is surprisingly lightweight and weighs twice as less as other, similar materials, which reduces transportation costs and the duration of installation.

Quick assembly

Since it’s lightweight, it’s easy to work, cut, and assemble. According to experts, this would mean that it requires 30% less time to build a structure (compared to traditional masonry constructions).

Cost-effective

As above-mentioned, using cellular concrete means reducing construction and insulation costs, on the long term.

Reduces carbon footprint

Cellular concrete is mainly composed of natural and recyclable materials, which makes it an overall eco-friendly product.

Overall, the manufacturing process of cellular concrete solely requires small amounts of natural resources and fossil fuels, meaning it’s non-pollutant. And, 90% of the amount of residual waste can be reused. However, the manufacturing process requires a significant amount of energy, and the water can be reused.

Durable

Unlike other materials with limited service lives, cellular concrete is as durable as a rock; it doesn’t deteriorate over time.

Great soundproofing

Sound bounces off cellular concrete, and reverts back to where it originates. A small part of the sound will also be absorbed by the concrete, which means that, overall, noise pollution inside is kept to a minimum.

Versatile

Cellular concrete is easy to make and is retailed in various forms. Beyond blocks and panels, you can obtain custom-made shapes (arches, pyramids, angles, etc.). This makes unique constructions a possibility.

Fireproof

Cellular concrete is both non-flammable and non-combustible, which makes building fireproof structures possible. On the flammability rating scale, it’s A1-classified with a 1,200°C melting point. If exposed to intense heat, the material won’t explode or crack.

Due to its low thermal conductivity, it’s not only ideal for building single-detached homes, but also for industrial, agricultural, and administrative buildings.

Waterproof

Since cellular concrete slows down water absorption, it can also regulate moisture levels inside the dwelling for greater comfort.

Additionally, it limits thermal bridges since it doesn’t have any openings susceptible to air seepage. This contributes to better thermal insulation and also reduces energy costs.

Rot-resistant

Cellular concrete is a porous material, but unlike other materials, it’s airtight and doesn’t allow water vapour to seep through buildings. This minimizes the risks of being faced with a mould or fungi problem.

Withstands compressive forces and reduces dead weight

The more dense the material, the more resistant it’ll be. By using a material that’s as lightweight as cellular concrete to build the load-bearing structure of a building, the building’s height can be increased as well as the number of storeys.

Buildings can also be built on smaller footings, with fewer pilings or smaller pile caps, requiring fewer rebar. This translates into lower construction costs and more space.

Self-levelling

Cellular concrete is lightweight and naturally self-levelling or self-consolidating. It can fill in even the smallest of cavities. However, it requires a flat installation surface.

CONS

Source: Canva

Fragile

Cellular concrete is nonetheless fragile and, unfortunately crumbly, which makes its installation process delicate. To prevent degradation, material-specific anchors or sealant must be used.

Cellular concrete is also more likely to crack than other materials.

A health hazard?

The dust created when cutting cellular concrete contains health-hazardous particles. It’s thus recommended to wear a mask to shield yourself. Furthermore, while the related studies are contradictory, cellular concrete may cause cancer or Alzheimer’s disease.

Eco-friendly, but…

Its production requires the use of non-renewable raw materials and its manufacturing process generates CO2 emissions.

Limited coating options

Cellular concrete can only be coated with a limited amount of products and material-specific paint.

What type of exterior plaster can be used?

To safeguard cellular concrete, since it’s a crumbly material that’s likely to crack, it does require a coat of exterior plaster (a plaster compound for rough surfaces like cellular concrete).

Once topped in a plaster compound, cellular concrete can be coated with paint, tiles, etc. The surface must be completely dry prior to applying the paint to prevent any surface adherence issues or cracking. Opt for a moisture-resistant and weatherproof paint.

How to Cut Cellular Concrete Blocks

Source: Canva

Given its composition, cellular concrete is easy to cut and doesn’t require any particular tools. A hand saw will work just fine, but remember to wear a mask to protect yourself from health-hazardous dust.

Tools to Use

Tungsten carbide-tipped hand saws can cut 7 to 15 cm thick tiles, or 20 to 50 cm thick blocks.

An alligator saw—a handheld electric saw with a carbide blade—can cut tiles and blocks.

A grinder with a 230 diamond blade can cut through, at most, 9 cm thick tiles, but it is necessary to check the capacity of the specific machine.

How should you go about it?

To mark cellular concrete with a cut guideline

Lay flat the block or tile.

Measure the required length and mark the cellular concrete with a guideline.

Extend the guideline over the entire surface of the tile or block using a large carpenter square.

To position the material to cut on a support

Position the support and item to be cut in alignment with where the intended cut will be.

To cut

Pile blocks or tiles atop each other to create a makeshift support.

Place the item to be cut cantilever-like on the support, based on where the intended cut will be made.

Start cutting at the opposite end, meaning the back side of the cellular concrete item.

Using a saw, angle the blade downward 45 degrees, then cut through to the underside.

Then, reduce the angle so that your cut is shallower yet longer, creating a raised guideline over the original marking.

Once the tip of the saw reaches the front edge of the item, angle your blade downward 45 degrees to finish the cut.

Can you build a house with this type of concrete in Canada?

Source: Canva

Cellular concrete is increasingly sought-after worldwide. However, the National Building Code of Canada renders its use a little more complex. It’s best to inquire prior to using it as intended.

Right now, cellular concrete has a relatively low MPa compressive strength rendering it non-compliant with the minimum standards required for standard concrete in all things foundation, ground-level slabs, and structural elements with rebar.

Also, note that an 8-inch thick (20 cm) cellular concrete wall isn’t especially energy-efficient in Canada since it only allows for an R-8 insulation value, while the minimum requirement is R-24.

Despite that, cellular concrete can make some genuinely beautiful structures, here and elsewhere. You just have to figure out which ones.

Get 3 quotes for your concrete-related project

RenoQuotes.com can help you get quotes from a general contractor. If you submit your project, we’ll connect you to top-rated contractors. Fill in the form on the homepage (it only takes a few minutes) and get estimates from trusted professionals.

Dial 1-844 828-1588 to speak with one of our customer service representatives.

Looking for something else?

Related articles

The latest industry news, interviews, technologies, and resources.

Editorial Team

•27 Aug 2025

Did you know that concrete could be recycled? Well, yes siree Bob! Concrete recycling is a technique used to salvage concrete waste. It’s an alternative to disposing of it in landfills that happens to be both cost-effective and eco-friendly. So, let’s zero in on concrete recycling, a practice that’s still, to this day, little known in Canada.

Editorial Team

•08 Nov 2023

When temperatures are soaring during those summer months, we’re all looking for a way to cool off. For homes without central air or other cooling systems, the task may be slightly more difficult. Ceilings fans are an arguably popular option, as they are an environmentally-friendly way to beat heat. Even if your home has air conditioning, ceiling fans can take away some of the strain on the system and during winter months, fans can work to circulate heat around the house.

Cynthia Pigeon

•21 Nov 2023

Do you know if your yard is properly drained? Have you noticed white powder on the concrete, mould at the bottom of the walls, water or wet concrete on the slab, or even a lingering humidity or a foul odour? Well, if so, it is about time to upgrade to a French drain!

Léa Plourde-Archer

•17 Jun 2025

As one of the main structural elements of your home, you must take proper and deliberate care of your roof. Of course, even with the best maintenance practices, there eventually comes a time when you’ll need to fix your roof. But how can you approach this large-scale project?

Karine Dutemple

•08 Nov 2023

If there is any certainty in this world, it is that there will always be dishonest people knocking on your door to try to extract money from you that you did not plan to spend.