Garbage disposals were invented in America in the late 1920s, but it was only during the postwar years that there was a growth in the installation of this device in the private homes of North Americans.

Nowadays, we’d say this tool isn’t as popular, in part because more and more municipalities across the country offer to compost. However, in some cases installing a shredder is still an attractive option.

In this article, we’re going to present the garbage disposal, the advantages and disadvantages, the different models, the prices, and what can and cannot be shredded by them.

What's the purpose of a garbage disposal?

The main purpose of garbage disposals is to pulverize food waste and depending on the model, sometimes other items. This tool works by shredding food into tiny particles to prevent it from blocking your pipes.

These devices are connected to sewers, so waste is sent to the sewage treatment plant (if you’re connected to the city system).

They’re installed below your sink, where the water flows to the drain. For cleaning, it’s recommended to insert ice cubes about once a month and activate the crusher. Of course, you should consult the manufacturer's recommendations for maintenance.

What are the advantages of a garbage disposal?

First of all, these devices are very easy to use. They reduce odours in the kitchen and help get rid of leftover food quickly. They also allow fewer sink blockages and make cleaning this part of the kitchen easier.

For those who don’t have access to composting amenities, garbage disposals also reduce the amount of waste that’s sent to the landfill.

Their disadvantages

These devices take up space (especially if you have a small kitchen). They are more environmentally friendly than composting (but if you have no other options, we’d say they’re better than nothing). In addition, they consume water and electricity. It’s important to know that these devices cannot crush metals, or plastics or get rid of chemical residues so you have to be careful what you put into them and your sink.

Also, if you don't choose the right model, the shredder itself can be noisy. Further, garbage disposals cannot be installed in some buildings. If you live in a condo, check the regulations. This is because the type of plumbing system installed in the building may not cooperate with garbage disposals.

You should also know that in some places, these devices are heavily regulated. For example, in Sherbrooke, where compost has been offered by the city for over 15 years, garbage disposals will soon be banned because of their impact on the city's sewer systems among other things. Check with your municipality before proceeding with this installation and to find out if there are exceptions.

What can you put down garbage disposals?

Here are the foods you can shred in most garbage disposals (as mentioned, please always consult the instruction manual that comes with your appliance):

Fruit and vegetable peels

Leftover meat (except bones)

Fish (including bones)

Walnut shells

Pastry

Eggshells (but beware of the membrane which can create problems)

Fruit stones (if your grinder is powerful)

Teabags (not plastic ones)

What can you not put down garbage disposals?

Here are the main foods and items that shouldn’t be put into this device:

Fat, oil, butter (if you do this, be sure to harden the fat using cold water before grinding)

Fibrous vegetables like celery and asparagus (if your grinder isn't strong enough)

Pasta

Rice

Coffee

Fruit stones (in less powerful models)

Bones (except fish bones)

What are the different garbage disposal models on the market?

As mentioned, the main part of the garbage disposal is installed under the sink, so the aesthetic appearance of this device doesn’t vary greatly from model to model.

The main differences between models are seen more in the level of the motor force, the size of the grinding chamber, the noise, and the lifespan of the device.

First, you should choose your model according to the number of people who live in your home. The more you are, the more powerful a machine you’ll need. Also, check that the model is suitable for your kitchen plumbing.

Lower-end models will have a shorter lifespan and will generally be noisier. Further, lower-quality materials will tend to be affected by corrosion more quickly.

Most models have a lifespan of between 8 to 15 years. Do bear in mind that higher-quality models will also consume less electricity and be more durable.

What's the average cost of a garbage disposal?

If you take a look at the websites of plumbing stores and home improvement superstores, you’ll likely notice a price difference between the models.

On average, most models of garbage disposals cost between $240 and $600 (some models cost up to $700, and others cost less than $200). It all depends on the power of the motor, the size of the chamber, and the other factors that we’ve presented in this article.

Before you buy, be sure to compare products by reading people's reviews.

Next, you must take into account the installation, usually done by a plumber, although some models pride themselves on being able to be installed by people with no experience.

To learn more about the fees charged by plumbers, see this article: Cost of Plumbing Renovations.

Get 3 renovation quotes for your garbage disposal installation

RenoQuotes.com can help you get quotes for your plumbing renovation project. If you submit your project to us, we’ll put you in contact with the appropriate contractors for your project. Fill in the form below (it only takes a few minutes), and you will receive quotes from trusted professionals.

Dial 1-844 828-1588 to speak with one of our customer service representatives.

Looking for something else?

Related articles

The latest industry news, interviews, technologies, and resources.

Editorial Team

•02 Aug 2024

The kitchen is a space of collaboration and cohabitation, where friends and family gather to cook, clean and hang out. Many important elements and fixtures occupy this room, and often overlooked is the humble backsplash.

Editorial Team

•21 Jan 2025

Natural stone countertops are favoured options in modern kitchens and bathrooms for their robusticity and timeless elegance. They add value to a house while also serving as durable work surfaces. But, when faced with a slew of available materials, how can you go about choosing the one that's best suited to your needs?

Editorial Team

•08 Nov 2023

Whether working, taking care of young ones, recovering from a cold or cooped inside for one reason or another, there are times when we’re stuck at home for days with no end in sight.

Editorial Team

•08 Nov 2023

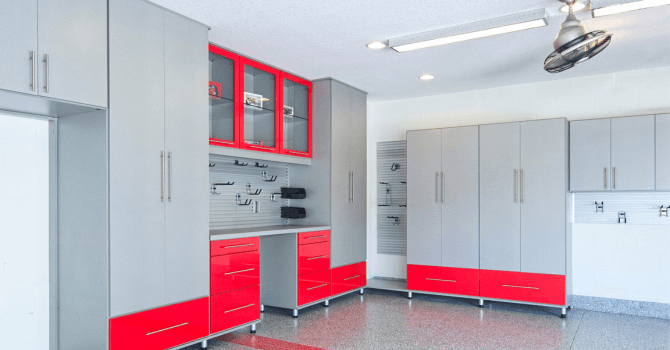

Have you finally decided to organize your garage and store away the tools that have just been piling up everywhere? Are you looking for the best storage system? If so, go for a garage storage cabinet! It’s a functional, utility cabinet that allows you to organize and secure your tools and other items. Learn more about the various types of garage storage cabinets, their features, and their advantages down below!

Christine Simard

•08 Nov 2023

Your kitchen and dining room are places for gatherings and festivities. Whether with family or with your partner, whether your kitchen is small or large, you need to have a space that is both practical and efficient in order to give you the possibility to prepare all your meals.